Advanced Aseptic Filling Solutions for Premium Fruit Juices

In the competitive fruit juice market, manufacturers face dual challenges: maintaining the nutritional integrity and flavor profiles that consumers demand while addressing growing concerns about preservatives and shelf stability. Newamstar’s specialized aseptic filling technology for fruit juices offers a comprehensive solution to these challenges—delivering systems that preserve nutritional value, enhance shelf life, and maintain the vibrant flavors that differentiate premium juice products.

This article explores how Newamstar’s aseptic filling solutions are specifically engineered to address the unique requirements of fruit juice production, examining the technological innovations that ensure product integrity, production efficiency, and market differentiation in this demanding beverage category.

Preserving Nutritional Value: The Juice Integrity Challenge

Fruit juices present unique challenges for preservation due to their nutrient-rich composition, making them particularly susceptible to degradation through conventional thermal processing. Newamstar’s aseptic technology addresses these challenges through specialized approaches designed specifically for juice products.

Advanced Thermal Processing Optimization

Newamstar’s systems incorporate juice-specific thermal profiles that maximize preservation while minimizing nutritional degradation:

Precision Thermal Management

Ultra-rapid heating and cooling cycles with temperature precision of ±0.5°C, minimizing thermal exposure while ensuring complete pathogen elimination and maintaining up to 98% of heat-sensitive vitamins.

Vitamin Retention Technology

Dedicated processing parameters for different juice varieties with custom thermal profiles for citrus, berry, and tropical fruit formulations and reduced oxygen exposure throughout the process.

Color Preservation

Specialized processing techniques maintaining anthocyanins and carotenoids with minimal oxidation through inert gas flushing and robust degradation prevention for natural pigments.

Enzyme Management

Precision inactivation of quality-degrading enzymes while preserving beneficial compounds with tailored thermal protocols for pectinase and polyphenol oxidase inactivation.

Flavor Profile Maintenance

Preserving the delicate flavor compounds that differentiate premium juice products requires specialized processing considerations:

Volatile Compound Retention

Specialized pressure control during thermal processing with rapid cooling phases minimizing volatile loss and closed-system processing preventing aroma compound evaporation.

Flavor Stabilization

Juice-specific oxygen management throughout processing with headspace management technology minimizing oxidation reactions and specialized container designs preserving flavor compounds during shelf life.

Sensory Validation

Integrated production testing with comparative sensory analysis ensuring flavor profile consistency and real-time adjustments maintaining established flavor benchmarks.

Fresh-Equivalent Results

Sensory testing confirms up to 95% flavor similarity to fresh-processed juice with significant improvement over conventional pasteurization, allowing “fresh-like” product positioning.

Optimized Processing for Juice Varieties

Recognizing that different juice types present unique processing challenges, Newamstar’s systems incorporate specialized adaptations:

Specialized Processing by Juice Type

- Citrus Juices: Specialized processing preventing limonene degradation and bitter compound development with integrated de-aeration systems minimizing vitamin C loss

- Berry Juices: Rapid thermal processing preserving anthocyanins and polyphenols with enhanced temperature monitoring for these heat-sensitive products

- Apple & Pear Juices: Custom processing parameters preventing enzymatic browning with specific thermal profiles inactivating polyphenol oxidase

- Tropical Fruit Juices: Specialized systems handling higher viscosity and fiber content with custom flow dynamics for mango, pineapple, and similar fruits

- Blended Juice Products: Adaptive processing for multi-component products with parameter optimization for the most sensitive ingredients in blends

Pulp Management: Maintaining Natural Texture

Unlike many beverage categories, premium juice products often contain pulp or fiber components that require specialized handling throughout the aseptic process.

“Traditional aseptic systems often struggle with pulp-containing juices, resulting in pulp damage, uneven distribution, or clogging issues. Newamstar’s dedicated fruit juice technology incorporates specialized design features that maintain pulp integrity throughout the process, preserving the natural mouthfeel that consumers associate with premium juice products.”

Advanced Homogenization Control

Variable pressure homogenization with juice-specific settings maintaining desired pulp structure, product-specific shear rate management preserving natural juice texture, and homogenizer bypass options for pulp-rich formulations.

Specialized Valve Technology

Large-diameter flow paths accommodating pulp particles without damage, gentle-action valves minimizing shear forces on pulp components, and specialized seat designs preventing pulp accumulation and ensuring sterility.

Fiber-Optimized Filling Technology

Specialized filling valves maintaining pulp suspension during dispensing, volumetric filling systems ensuring consistent pulp-to-liquid ratios, and agitation systems preventing settling during production runs.

Enhanced Shelf Life Without Preservatives

For juice producers, achieving extended shelf life without chemical preservatives represents a significant market advantage, addressed through Newamstar’s comprehensive aseptic approach:

Contamination Prevention

Multi-zone protection with separate sterile zones, HEPA-filtered positive pressure environments, and automated sterile barrier maintenance achieving contamination rates below 0.001%.

Container Sterilization

Specialized sterilization technologies for juice packaging with customized hydrogen peroxide concentrations and ultraviolet light treatment ensuring 6-log reduction in contaminants.

Shelf Life Extension

Ambient storage capability for up to 12 months without preservatives, maintained nutrient profiles throughout shelf life, and consistent organoleptic properties from production to consumption.

Clean Label Support

Elimination of preservatives, stabilizers, and artificial additives through physical preservation methods, enabling simplified ingredient lists aligned with clean label consumer preferences.

Production Efficiency for Juice Operations

Beyond product quality benefits, Newamstar’s juice-specific aseptic technology delivers operational advantages addressing the economic challenges of juice production:

Rapid Product Changeover

Specialized CIP/SIP systems with product-specific cleaning protocols for juice residues, automated changeover sequences reducing transition times by 35-45%, and specialized product recovery systems minimizing product loss during transitions.

Seasonal Production Flexibility

Adaptable production capacity for seasonal harvest cycles, rapid scaling capabilities for peak production periods, and efficient operation across varied production volumes supporting local sourcing models.

Pulp Handling Reliability

Specialized components preventing pulp-related downtime with robust designs eliminating clogging in high-fiber formulations and specialized monitoring preventing pulp accumulation in critical components.

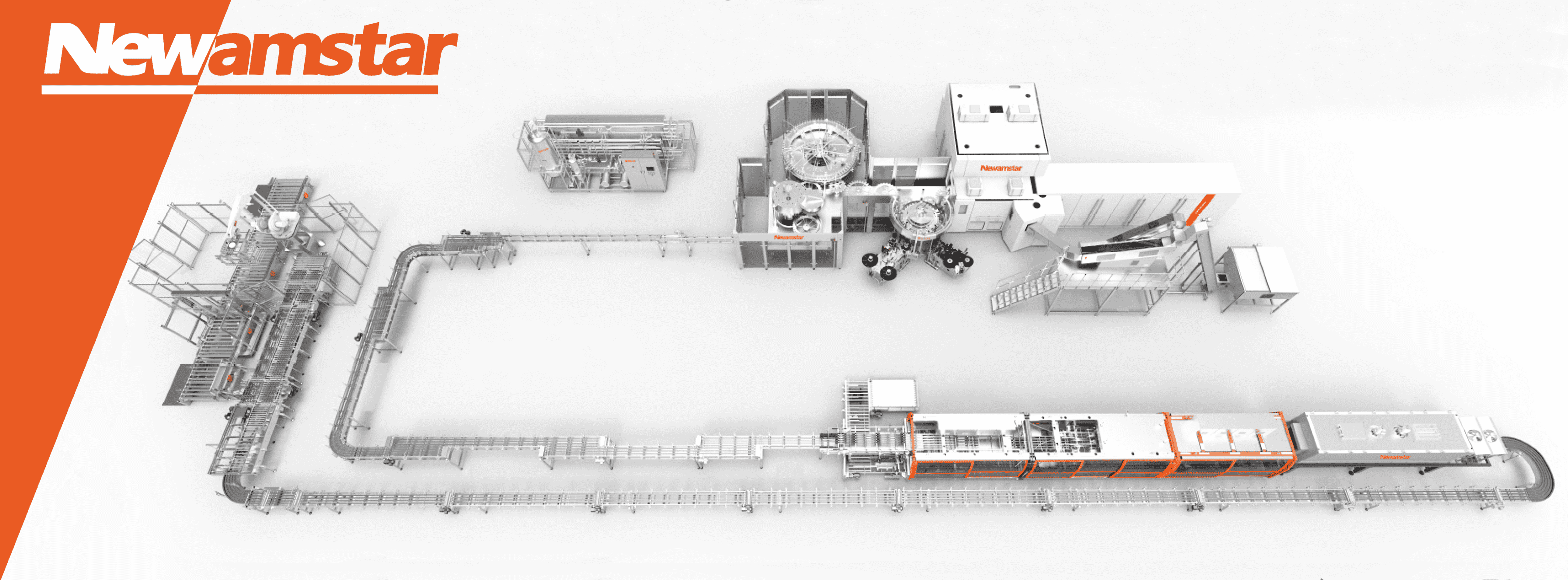

High-Speed Production

Processing capacities up to 48,000 bottles per hour while maintaining quality parameters with rapid changeover capabilities between bottle sizes and reliably handling diverse juice viscosities at high speeds.

Case Studies: Juice Producers See Real Results

Newamstar’s specialized juice aseptic technology has delivered transformative results across diverse juice operations:

Premium Citrus Juice Producer

Tropical Juice Manufacturer

Future Innovations: Next-Generation Juice Processing

Newamstar continues to develop advanced technologies specifically enhancing juice production capabilities:

Non-Thermal Preservation

High-pressure processing integration options preserving heat-sensitive components, advanced pulsed electric field technologies for selective microbial inactivation, and ultraviolet treatment systems enhancing quality retention.

AI-Driven Quality Optimization

Real-time spectroscopic analysis maintaining optimal flavor profiles, machine learning algorithms predicting and preventing quality deviations, and automated processing adjustments based on input fruit characteristics.

Advanced Packaging Solutions

Next-generation barrier technologies further extending ambient shelf life, innovative packaging materials enhancing sustainability, and smart packaging options providing consumers with freshness indicators and product information.

Environmental Leadership Through Innovation

Newamstar’s aseptic filling technology represents more than merely an operational solution—it embodies a comprehensive approach to environmental sustainability in beverage manufacturing. By simultaneously addressing multiple environmental dimensions—energy, water, waste, packaging, and lifecycle impacts—these systems deliver meaningful progress toward sustainability objectives.

For beverage manufacturers navigating increasingly stringent environmental regulations, growing consumer environmental consciousness, and corporate sustainability commitments, Newamstar’s technology offers a powerful tool for environmental improvement. The documented results across diverse implementations demonstrate that environmental benefits need not come at the expense of operational performance or product quality—indeed, properly implemented aseptic technology enhances all these dimensions simultaneously.

“As the beverage industry continues its sustainability journey, Newamstar’s commitment to continuous environmental innovation ensures that its aseptic filling technology will remain at the forefront of environmentally responsible manufacturing solutions. For forward-thinking beverage producers, this technology represents not merely a production solution but a strategic asset in building a more sustainable future for the industry.”

Global Impact and Industry Recognition

Throughout its evolutionary journey, Newamstar has successfully delivered over 2,300 production lines to customers across more than 100 countries and regions worldwide. The company’s aseptic filling technology has been embraced by international beverage giants including Coca-Cola, PepsiCo, Danone, and Nestlé, as well as leading domestic brands like Master Kong, Wahaha, and Nongfu Spring.

As a testament to its technical excellence, Newamstar has received numerous industry accolades and holds over 500 invention patents, many specifically related to aseptic filling innovations. This recognition reflects not only the company’s technological capabilities but also its commitment to driving industry advancement.

Key Achievements in Aseptic Filling Technology

Learn More About Newamstar’s Juice Processing Solutions

Discover how Newamstar’s comprehensive aseptic technology can help you achieve exceptional juice quality, extended shelf life, and operational excellence with your fruit juice production.