Quality Control Systems in Newamstar Aseptic Solutions

In aseptic beverage production, quality isn’t merely a goal—it’s an absolute requirement. While safety represents the foundation of aseptic processing, comprehensive quality encompasses much broader dimensions including consistency, sensory characteristics, nutritional integrity, and package performance. For beverage manufacturers, delivering these quality attributes consistently is essential for brand reputation and market success.

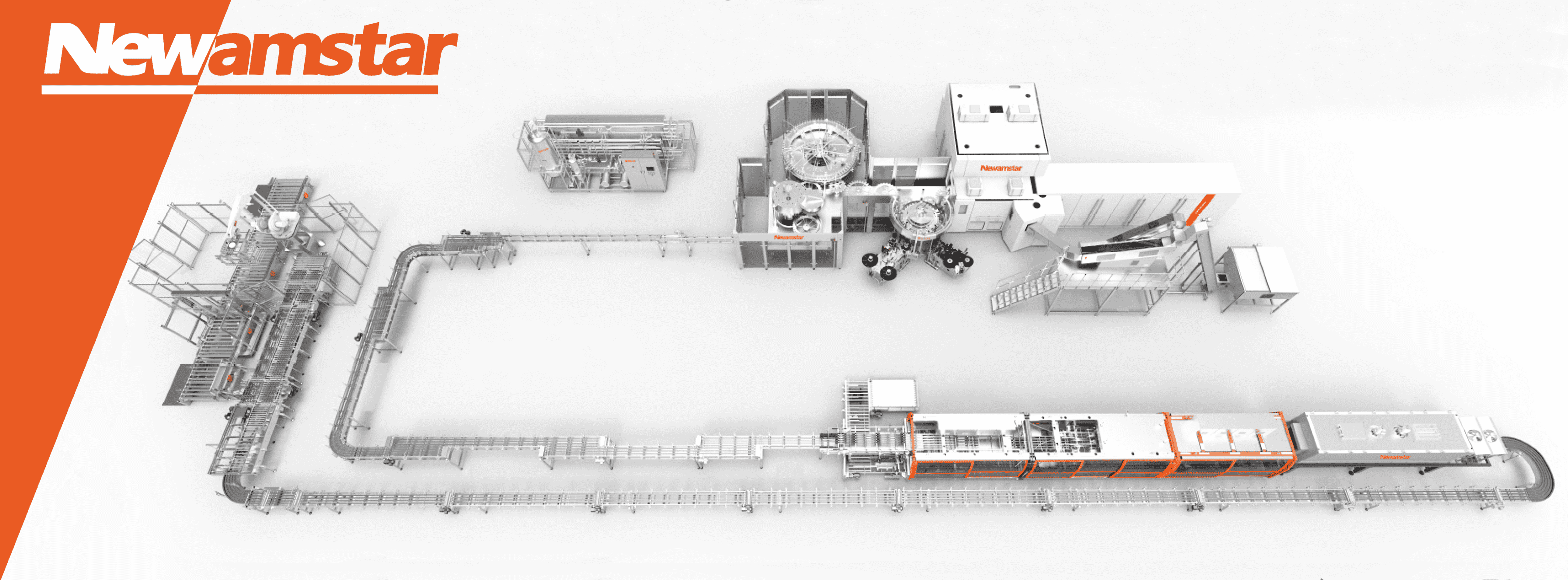

Newamstar’s aseptic filling technology incorporates sophisticated quality control systems addressing every aspect of product and package quality throughout the production process. This article explores the philosophical approach, technical methodologies, and practical implementation of quality assurance within Newamstar’s systems, revealing how these capabilities deliver the consistent excellence essential in premium beverage markets.

Quality Philosophy: The Foundational Approach

Newamstar’s approach to quality control begins with fundamental philosophical principles guiding system design and operation:

Quality by Design

Rather than relying solely on inspection to catch defects, Newamstar employs QbD principles:

Quality Attribute Definition

Quality attributes defined during initial system specification, establishing clear targets for all aspects of product and package performance.

Parameter-Focused Design

Process parameters designed specifically to deliver these attributes, with clear understanding of how each parameter influences quality outcomes.

Design Space Development

Identifying acceptable operating ranges that ensure quality delivery, providing flexibility while maintaining consistent results.

Risk Assessment

Identifying potential quality impact points throughout the process, allowing focused control strategy development and resource allocation.

Total Quality Management Integration

Newamstar’s systems support TQM methodologies through:

Process Capability Analysis

Confirming consistent quality delivery through statistical evaluation of process performance relative to specifications.

Statistical Process Control

Implementation at critical control points ensuring process stability and early detection of quality trends.

Quality Data Integration

Connecting with enterprise systems to create seamless quality information flow throughout the organization.

Continuous Improvement

Mechanisms for ongoing enhancement driven by quality data analysis and operational learning.

Risk-Based Quality Approach

Resources focus on areas with greatest quality impact through:

Key Risk Management Strategies

- Failure Mode and Effects Analysis (FMEA): Systematic evaluation of potential failure modes for process steps

- Hazard Analysis Critical Control Point (HACCP): Implementation identifying critical safety and quality control points

- Quality Risk Prioritization: Strategic resource allocation based on potential quality impact

- Preventive Action Focus: Concentration on high-risk areas to prevent quality issues

- Verification Concentration: Focused verification activities on critical quality attributes

Product Quality Assurance: Ensuring Consumable Excellence

The primary quality focus naturally centers on the beverage itself, with Newamstar’s systems providing comprehensive product quality control:

Thermal Process Verification

For products requiring thermal treatment, precise process verification ensures:

Time-Temperature Profiles

Adherence throughout the heat treatment process with continuous monitoring and verification.

Temperature Uniformity

Distribution validation ensuring consistent processing throughout the product volume.

F-Value Calculations

Confirming adequate thermal processing for safety while preventing excessive treatment.

Cooling Profile Management

Preserving product characteristics through controlled cooling after thermal treatment.

“Advanced technologies including magnetic flow metering, distributed temperature sensors, and computational modeling ensure consistent delivery of specified thermal processes, balancing safety requirements with quality preservation.”

Microbial Control Validation

Beyond process parameters, direct microbial validation confirms effectiveness:

Pre-Sterilization Assessment

Bioburden assessment establishing baseline contamination levels prior to processing.

Post-Sterility Testing

Microbiological testing confirming effective sterilization after processing.

Environmental Monitoring

Continuous monitoring throughout the aseptic zone ensuring sterility maintenance.

Challenge Testing

Deliberate introduction of test organisms during validation to verify process effectiveness.

Sensory Quality Preservation

Preserving desired sensory characteristics requires specialized approaches:

Oxygen Management

Throughout the process minimizing oxidation with deaeration, nitrogen blanketing, and dissolved oxygen monitoring to preserve flavor and color stability.

Light Exposure Control

Preventing photochemical degradation through shielded processing areas and packaging with appropriate light barrier properties.

Temperature Profile Optimization

Preserving flavor compounds through precise thermal treatment minimizing heat exposure while ensuring safety.

Packaging Quality Control: Ensuring Container Integrity

For aseptic products, packaging integrity is inseparable from product quality, requiring comprehensive verification:

Advanced Vision Systems

360° surface inspection with multiple camera positions and specialized lighting for comprehensive defect detection.

Closure Verification

Application torque monitoring, placement accuracy verification, and leak detection confirming proper sealing.

Barrier Property Testing

Verification of oxygen transmission, light barrier effectiveness, and moisture vapor transmission properties.

Seal Integrity Testing

Pressure decay testing, vacuum testing, and burst pressure evaluation ensuring complete package integrity.

Process Control Systems: Ensuring Consistent Quality Delivery

Beyond specific product and package attributes, Newamstar’s systems implement comprehensive process control ensuring consistent quality:

Parameter Monitoring

Distributed sensing technologies with redundant measurements for critical parameters ensuring reliable data.

Statistical Process Control

Real-time SPC with control charts, trend analysis, and capability monitoring ensuring process stability.

Automated Adjustment

Closed-loop control systems maintaining optimal conditions despite external variations in materials or environment.

Cleaning Verification

Conductivity monitoring, temperature mapping, and flow verification ensuring effective cleaning and sterilization.

Case Study: Quality Excellence in Action

The comprehensive impact of Newamstar’s quality systems is illustrated through real-world implementation:

Premium Tea Producer Results

Future Quality Horizons: Emerging Technologies

As quality expectations continue rising, Newamstar remains at the forefront of quality technology development:

Artificial Intelligence Applications

Computer vision, natural language processing, deep learning models, and autonomous optimization transforming quality management capabilities.

Blockchain for Quality Traceability

Distributed ledger technology creating immutable batch records, end-to-end traceability, and enhanced transparency throughout the value chain.

Augmented Reality Quality Support

Visual inspection guidance, real-time data visualization, and remote expert consultation enhancing human quality management capabilities.

Conclusion: Quality as Competitive Differentiation

Newamstar’s comprehensive approach to quality control represents more than technical sophistication—it embodies a fundamental recognition that in premium beverage markets, quality consistency creates meaningful competitive differentiation. By integrating advanced technologies, statistical methodologies, and quality management principles, these systems deliver the consistent excellence consumers expect from premium beverages.

“As consumer quality expectations continue rising and regulatory requirements become increasingly stringent, Newamstar’s commitment to quality innovation ensures its systems will remain at the forefront of aseptic filling technology—delivering not merely safe products, but consistently excellent beverages worthy of premium positioning in competitive global markets.”

Global Impact and Industry Recognition

Throughout its evolutionary journey, Newamstar has successfully delivered over 2,300 production lines to customers across more than 100 countries and regions worldwide. The company’s aseptic filling technology has been embraced by international beverage giants including Coca-Cola, PepsiCo, Danone, and Nestlé, as well as leading domestic brands like Master Kong, Wahaha, and Nongfu Spring.

As a testament to its technical excellence, Newamstar has received numerous industry accolades and holds over 500 invention patents, many specifically related to aseptic filling innovations. This recognition reflects not only the company’s technological capabilities but also its commitment to driving industry advancement.

Key Achievements in Aseptic Filling Technology

Learn More About Newamstar’s Validation Services

Discover how Newamstar’s comprehensive validation approach can help you achieve regulatory compliance, product safety, and operational excellence with your aseptic filling systems.