Smart Industry 4.0 Applications in Newamstar Manufacturing

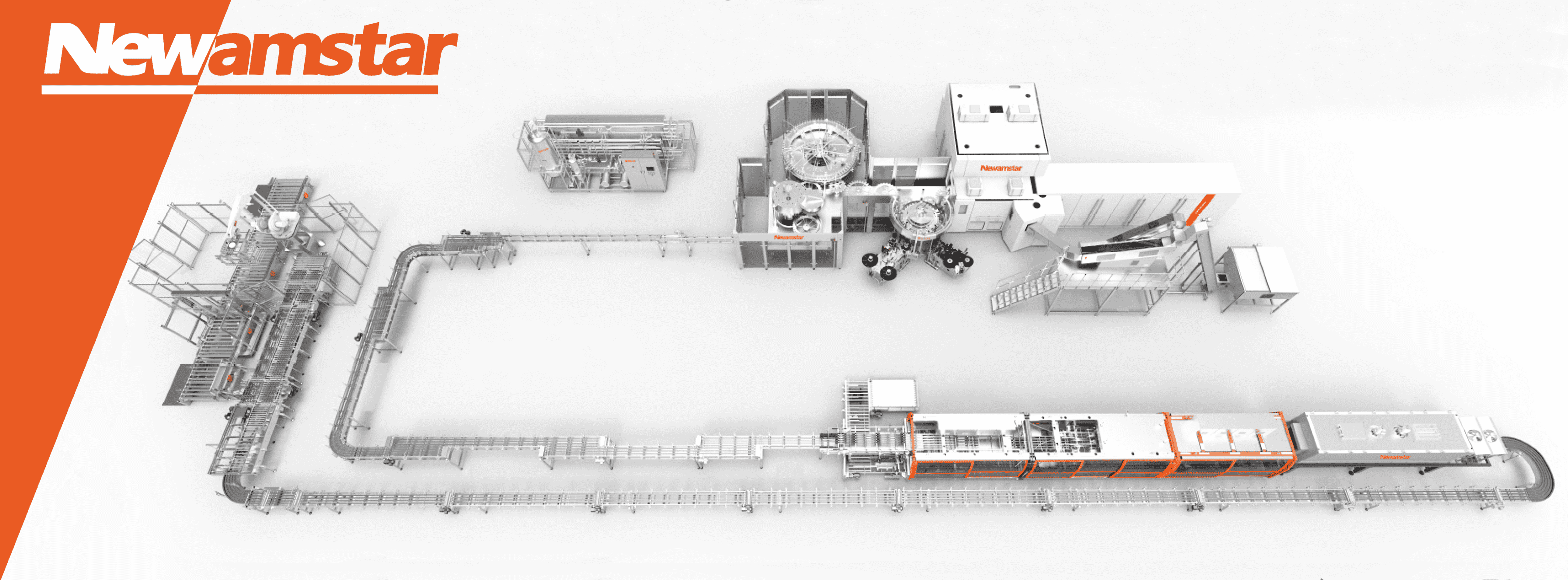

The fourth industrial revolution—commonly known as Industry 4.0—has transformed manufacturing across sectors through the integration of digital technologies, connectivity, and intelligent systems. In the beverage industry, this digital transformation offers tremendous opportunities to enhance efficiency, quality, flexibility, and sustainability. As a technology leader in liquid packaging, Newamstar has been at the forefront of implementing Industry 4.0 principles in aseptic filling systems, creating intelligent production platforms that redefine manufacturing capabilities.

This article explores how Newamstar’s aseptic filling technology embraces Industry 4.0 concepts, examining the specific technologies, implementation approaches, and practical benefits for beverage manufacturers. By understanding these advanced capabilities, producers can better appreciate how modern aseptic systems transcend traditional equipment to become integrated smart manufacturing platforms.

Industry 4.0 Foundations in Newamstar’s Systems

Newamstar’s approach to Industry 4.0 integration builds upon several foundational technological capabilities:

Comprehensive Digitalization

Digital technology forms the essential foundation for Industry 4.0 implementation:

Digital Control Architecture

Fully digital control systems replacing traditional analog approaches, enabling precise parameter management and comprehensive data collection.

Sensor Networks

Advanced sensing technologies providing complete process visibility through continuous monitoring of critical parameters.

Digital Twins

Virtual representations of physical systems enabling simulation, optimization, and predictive analysis before implementation.

Paperless Documentation

Electronic records management systems replacing traditional paper-based documentation, improving accuracy and accessibility.

Ubiquitous Connectivity

Beyond individual digital components, connectivity creates system-wide intelligence:

Industrial Ethernet

Robust communication backbone with deterministic protocols ensuring reliable, real-time data transmission throughout the system.

OPC-UA Implementation

Standardized data exchange protocols enabling seamless communication between diverse system components.

Secure Cloud Connectivity

Protected data sharing capabilities extending system visibility beyond the production facility to enterprise systems.

IoT Capabilities

Connecting previously isolated components into an integrated information ecosystem for comprehensive monitoring and control.

“Comprehensive connectivity transforms isolated machines into cohesive systems, enabling coordinated operation and creating the foundation for truly intelligent manufacturing. Newamstar’s systems integrate diverse components into a unified production ecosystem.”

Key Industry 4.0 Technologies in Newamstar’s Systems

Building on these foundations, Newamstar implements several specific Industry 4.0 technologies enhancing aseptic filling capabilities:

IoT Sensor Networks

Advanced sensing creates unprecedented process visibility through smart sensors with self-diagnostic capabilities, wireless networks reducing installation complexity, and multi-parameter sensors providing comprehensive monitoring.

Big Data Analytics

Converting vast data volumes into actionable insights through real-time analytics providing immediate operational guidance, batch analytics identifying long-term patterns, and scalable frameworks handling growing information volumes.

Artificial Intelligence Applications

Beyond conventional analytics, AI enables advanced capabilities through machine learning identifying complex patterns, computer vision enhancing inspection, and anomaly detection identifying subtle deviations from normal operation.

Augmented and Virtual Reality

Enhanced visualization technologies improve human interaction through AR maintenance guidance providing visual work instructions, virtual training simulations, and remote expert support through shared visual environments.

Autonomous Systems

Increasing autonomy reduces dependence on human intervention through self-adjusting processes maintaining optimal parameters, autonomous material handling, and self-scheduling maintenance based on condition monitoring.

Advanced Robotics

Modern robotics extends automation beyond traditional boundaries with collaborative robots working alongside human operators, flexible systems adapting to multiple tasks, and vision-guided robots handling variable product arrangements.

Implementation Architecture: Bringing Technologies Together

Newamstar’s Industry 4.0 implementation follows a structured architecture integrating these technologies into a cohesive system:

Five-Layer Implementation Model

- Physical Layer: The foundation comprising actual production equipment with embedded sensors and digital control capabilities

- Connection Layer: Technology connecting physical systems to digital networks through industrial protocols and IoT gateways

- Edge Layer: Local processing providing real-time capabilities through edge computing and immediate operational analytics

- Platform Layer: Enterprise-level integration and analysis through MES, historian databases, and digital twin environments

- Enterprise Layer: Business integration completing the digital thread with ERP, supply chain, and business intelligence connections

Information Flow Pathways

Within this architecture, several critical information flows enable Industry 4.0 functionality:

Vertical Integration

Connecting shop floor to top floor through bi-directional communication enabling agile response to changing conditions and real-time performance visualization.

Horizontal Integration

Connecting across the value chain with supplier integration providing material traceability and customer connectivity enabling demand-driven production.

Temporal Integration

Connecting past, present, and future through historical data providing context, real-time information supporting immediate decisions, and predictive capabilities.

Simulation Capabilities

Testing potential scenarios before implementation, enabling risk-free exploration of process adjustments and optimization strategies.

Practical Applications: Industry 4.0 Benefits in Aseptic Operations

Newamstar’s Industry 4.0 implementation delivers tangible benefits across multiple operational dimensions:

Operational Excellence Enhancements

Smart systems drive performance improvement through:

Predictive Quality Management

Moving beyond reactive quality control with real-time parameter monitoring identifying deviations before specifications are exceeded, reducing quality incidents by 40-60%.

Efficiency Optimization

Intelligent systems continuously maximize productivity through energy optimization, production sequencing, and throughput maximization, delivering 15-25% efficiency improvements.

Predictive Maintenance

Moving beyond scheduled interventions with condition monitoring detecting developing issues before failures occur, reducing unplanned downtime by 30-50%.

Flexible Production

Adapting quickly to changing requirements through rapid changeover systems, digital recipe management, and economical small-batch production capabilities.

Enhanced Business Agility

Beyond operational improvements, Industry 4.0 capabilities enhance overall business responsiveness:

Demand-Responsive Production

Connecting production directly to market signals through real-time demand visibility influencing production scheduling, automated production adjustment based on sales patterns, and inventory optimization reducing working capital requirements.

Supply Chain Resilience

Mitigating disruption through enhanced visibility with material traceability throughout the supply chain, early warning of potential supply disruptions, and alternative sourcing scenarios for critical materials.

Sustainable Manufacturing

Industry 4.0 capabilities deliver significant sustainability benefits through energy consumption monitoring and optimization, water usage minimization, and raw material utilization maximizing yield, typically reducing resource consumption by 20-30%.

Case Study: Industry 4.0 Implementation Success

The transformative impact of Newamstar’s Industry 4.0 technology is illustrated through actual implementation results:

Global Beverage Manufacturer Results

“These results delivered return on investment within 18 months, demonstrating the compelling business case for Industry 4.0 implementation in aseptic filling operations.”

Implementation Approach: The Journey to Smart Manufacturing

Implementing Industry 4.0 capabilities represents a significant transformation requiring strategic approach. Newamstar supports this journey through a structured methodology:

Maturity Assessment

Beginning with objective evaluation of current capabilities through technology infrastructure assessment and organizational readiness evaluation.

Roadmap Development

Creating a strategic implementation plan with phased priorities, technology selection aligned with business objectives, and ROI analysis for each phase.

Pilot Implementation

Beginning with controlled implementation scope including baseline documentation, focused implementation, and learning capture for broader deployment.

Scale Implementation

Expanding successful pilots across operations with standardized methodology, knowledge transfer, and integration across multiple production areas.

Future Horizons: Moving Beyond Industry 4.0

While current Industry 4.0 implementations deliver impressive results, Newamstar continues developing next-generation capabilities extending these benefits:

Cognitive Manufacturing

Moving toward truly intelligent production systems with self-learning capabilities continuously optimizing performance, cognitive quality management anticipating issues, and adaptive process control responding to changing conditions.

Digital Ecosystem Integration

Extending beyond enterprise boundaries with cross-enterprise optimization throughout the value chain, distributed production networks, and blockchain-enabled traceability ensuring product authenticity.

Sustainability 4.0

Leveraging digital capabilities for environmental leadership with carbon footprint optimization through AI-driven process control, circular economy enablement through digital material tracking, and zero-waste manufacturing through closed-loop monitoring.

Conclusion: The Strategic Imperative of Industry 4.0

Newamstar’s implementation of Industry 4.0 technologies in aseptic filling systems represents more than incremental improvement—it constitutes a fundamental transformation in manufacturing capability. For beverage producers navigating increasingly competitive markets with demanding consumers and complex regulatory requirements, these smart manufacturing capabilities provide strategic advantages across multiple dimensions:

Operational Excellence

Delivering cost leadership through efficiency and quality improvements that drive competitive advantage in demanding markets.

Market Responsiveness

Enabling rapid adaptation to changing consumer preferences through flexible production and accelerated innovation capabilities.

Sustainability Leadership

Supporting environmental initiatives with measurable results through resource optimization and waste reduction technologies.

Risk Mitigation

Enhancing resilience against supply chain and operational disruptions through predictive capabilities and enhanced visibility.

“As the beverage industry continues evolving toward greater product diversity, higher quality standards, and intensified sustainability focus, Newamstar’s Industry 4.0-enabled aseptic filling technology provides a powerful platform for competitive advantage. By embracing these digital capabilities, manufacturers position themselves not merely to survive industry transformation but to lead it—creating the smart factories that will define beverage production in the decades ahead.”

Global Impact and Industry Recognition

Throughout its evolutionary journey, Newamstar has successfully delivered over 2,300 production lines to customers across more than 100 countries and regions worldwide. The company’s aseptic filling technology has been embraced by international beverage giants including Coca-Cola, PepsiCo, Danone, and Nestlé, as well as leading domestic brands like Master Kong, Wahaha, and Nongfu Spring.

As a testament to its technical excellence, Newamstar has received numerous industry accolades and holds over 500 invention patents, many specifically related to aseptic filling innovations. This recognition reflects not only the company’s technological capabilities but also its commitment to driving industry advancement.

Key Achievements in Aseptic Filling Technology

Learn More About Newamstar’s Industry 4.0 Solutions

Discover how Newamstar’s smart aseptic filling systems can transform your beverage production with enhanced efficiency, quality, and sustainability through advanced Industry 4.0 technologies.