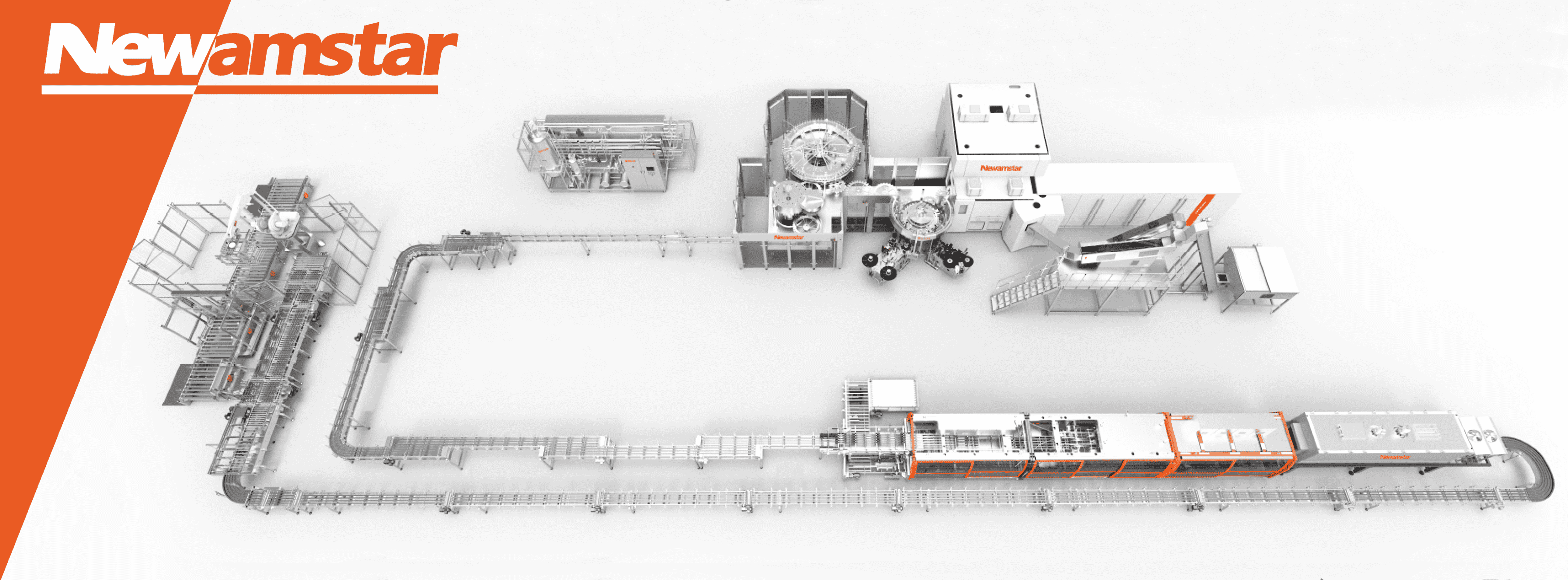

Newamstar Complete Dairy Processing Ecosystem Overview

In the intensely competitive dairy beverage market, manufacturers face a complex convergence of challenges: preserving delicate nutritional components while ensuring microbiological safety, extending shelf life while maintaining fresh sensory profiles, and meeting stringent regulatory requirements while enhancing operational efficiency. Newamstar’s specialized aseptic filling technology for dairy beverages addresses these multifaceted challenges with an integrated systems approach—delivering solutions that protect sensitive dairy proteins, ensure microbial safety, and preserve the sensory qualities that define premium dairy products.

This article explores how Newamstar’s dairy-specific aseptic filling systems overcome the unique processing challenges presented by milk-based beverages, examining the advanced technologies that enable extended shelf life without compromising nutritional integrity or flavor profiles—creating new market opportunities and operational advantages for dairy producers worldwide.

The Dairy Challenge: Preserving Nature’s Perfect Food

Dairy products represent one of the most nutritionally complex and microbiologically sensitive beverage categories, requiring specialized processing approaches beyond standard aseptic capabilities. Newamstar’s dairy-specific technology addresses these distinctive challenges through purpose-built systems.

Protein Preservation: The Cornerstone of Dairy Quality

The nutritional and functional properties of dairy beverages depend heavily on maintaining the native structure of milk proteins—a significant technical challenge during thermal processing:

Precision Thermal Management

Ultra-rapid heating with holding time precision of ±0.1 seconds minimizing protein exposure to high temperatures, specialized cooling profiles preserving protein native state, and precise temperature control within ±0.3°C throughout the process ensuring consistent protein quality.

Advanced Protein Monitoring

Real-time protein denaturation assessment capabilities with inline monitoring of key protein quality indicators and process adjustment algorithms maintaining optimal protein structural integrity throughout production runs.

Optimized Heat Exchangers

Specialized plate designs preventing protein deposition and fouling with dairy-specific flow dynamics reducing protein adsorption to surfaces and advanced surface treatments minimizing protein-surface interactions during thermal processing.

Formulation-Specific Processing

Customizable processing parameters for different protein profiles with specialized settings for high-protein functional beverages and adaptive processing for varying protein formulations from skim to whole milk products.

Fat Stability Assurance

The fat component in dairy beverages presents unique processing challenges requiring specialized handling to maintain stability and sensory quality:

Advanced Homogenization

Two-stage homogenization with precise pressure control ensuring optimal fat globule sizing (0.5-0.8 μm), specialized valve geometries minimizing protein shearing during homogenization, and temperature-controlled homogenization optimizing fat crystallization patterns.

Fat Oxidation Prevention

Specialized deaeration systems removing oxygen to levels below 0.5 ppm with controlled filling headspace minimizing oxidation potential and advanced packaging providing light and oxygen barriers throughout shelf life.

Cream Line Prevention

Advanced processing preventing fat separation during extended shelf storage with optimized homogenization for long-term stability and specialized handling for high-fat formulations maintaining homogeneity throughout shelf life.

Temperature Transition Management

Precise heating and cooling curves preventing adverse fat crystallization with controlled temperature transitions maintaining ideal fat globule membrane integrity and specialized cooling regimes preserving sensory attributes of milk fat.

Microbiological Safety: Beyond Standard Aseptic

The nutrient-rich composition of dairy beverages creates an ideal environment for microbial growth, requiring enhanced microbiological control beyond standard aseptic measures:

Enhanced Dairy Safety System

- Ultra-High Temperature Precision: Enhanced UHT systems achieving consistent 12D reduction of Clostridium botulinum with validated heat distribution studies ensuring no cold spots and customized time-temperature profiles for different dairy formulations

- Advanced Environmental Isolation: ISO Class 5 (Class 100) clean room environments for filling operations with specialized air handling systems optimized for dairy environments and enhanced positive pressure differentials between critical zones

- Specialized Container Sterilization: Enhanced container treatment protocols exceeding standard parameters with optimized hydrogen peroxide concentrations for dairy applications and extended UV exposure ensuring elimination of dairy-specific spoilage organisms

- Enhanced CIP/SIP Systems: Dairy-specific cleaning protocols addressing protein and fat residues with specialized caustic and acid phases optimized for dairy soils and extended sterilization cycles targeting biofilm-forming thermophilic organisms

- Microbial Monitoring: Comprehensive environmental and product testing protocols with rapid detection systems for dairy-specific pathogens and continuous monitoring throughout production runs

Specialized Solutions for Dairy Product Categories

Recognizing the diverse range of dairy beverage formulations in today’s market, Newamstar’s systems incorporate adaptive technologies for different product subcategories:

“Dairy beverages have evolved far beyond traditional white milk, encompassing a diverse spectrum of formulations from protein-fortified fitness drinks to specialty coffee creamers. Each product category presents unique processing challenges that standard aseptic systems often struggle to address. Newamstar’s customizable technology platform enables dairy manufacturers to optimize processing parameters for specific formulations, ensuring consistent quality across their entire product portfolio.”

White Milk Excellence

Precision thermal controls preventing cooked flavors with specialized deaeration preventing light-induced oxidation, dedicated homogenization settings optimized for different fat levels, and specialized handling preventing fat separation during extended shelf life.

Flavored Milk Processing

Specialized handling preventing flavor ingredient degradation with optimized processing for cocoa and other challenging ingredients, enhanced mixing systems ensuring uniform flavor distribution, and specialized parameters preventing sedimentation of flavor components.

Yogurt Drink Technology

Adaptive processing preserving live cultures when required with gentle handling maintaining characteristic texture and viscosity, specialized agitation preventing phase separation, and post-process addition capabilities for heat-sensitive probiotic strains.

Protein-Enhanced Formulations

Specialized thermal profiles preventing protein denaturation with heat exchanger designs minimizing fouling in high-protein products, gentle agitation preventing protein sedimentation, and optimized homogenization parameters preventing protein aggregation during shelf life.

Plant-Based Dairy Alternatives

Customized processing addressing unique characteristics of soy, almond, oat formulations with specialized homogenization parameters for plant protein stability, thermal profiles optimized to prevent beany off-notes, and specialized handling preventing calcium fortification sedimentation.

Coffee & Cream Beverages

Specialized processing preventing coffee-dairy component interactions with optimized parameters preventing precipitation in high-acid coffee environments, enhanced homogenization preventing cream separation, and specialized thermal profiles maintaining coffee aroma compounds.

Sensory Excellence: The Fresh Milk Experience

Beyond safety and shelf stability, Newamstar’s dairy aseptic technology focuses on delivering sensory profiles that closely match fresh dairy products—a critical factor for consumer acceptance and premium positioning:

Fresh Flavor Preservation

Minimal thermal exposure preventing development of cooked flavors with optimized time-temperature profiles maintaining authentic dairy notes and specialized cooling preventing formation of stale flavor compounds during processing.

Color Authenticity

Specialized processing preventing Maillard browning reactions with minimal oxygen exposure preserving natural milk whiteness and headspace management preventing discoloration during shelf life of white milk and flavored products alike.

Optimal Mouthfeel

Precise homogenization maintaining ideal texture characteristics with specialized processing preventing age gelation and viscosity changes and optimized cooling preserving the smooth, creamy texture consumers associate with fresh dairy.

Sensory Validation

Comprehensive sensory testing protocols comparing against fresh dairy benchmarks with consumer panel validation confirming similarity to fresh references and ongoing sensory monitoring throughout product shelf life ensuring consistency.

Production Efficiency for Dairy Operations

Newamstar’s dairy-focused aseptic technology addresses critical operational challenges specific to dairy production environments:

Fouling Prevention

Specialized plate heat exchangers designed to minimize protein fouling with optimized flow dynamics reducing deposit formation on heating surfaces, advanced surface treatments minimizing product adhesion, and strategic temperature distribution throughout heat exchangers reducing burn-on zones.

Extended Production Runs

Anti-fouling technologies extending production cycles between cleanings from 8-10 hours to 16-20 hours, resulting in 30-40% increased production capacity, advanced monitoring preventing quality deviations during extended operations, and intelligent scheduling algorithms optimizing production sequencing.

Enhanced CIP Efficiency

Optimized cleaning programs reducing CIP duration by 20-30% with specialized detergent formulations effectively removing protein and fat deposits, water-saving technologies reducing cleaning water consumption by 25-35%, and CIP recovery systems minimizing product and chemical waste.

Production Flexibility

Rapid changeover capabilities between different dairy formulations with easily adaptable processing parameters for varying fat content products, specialized tools enabling quick transitions between white milk and flavored dairy beverages, and efficient line clearance protocols minimizing product waste during transitions.

Case Studies: Dairy Producers Achieve Market Leadership

Newamstar’s specialized dairy aseptic technology has delivered transformative results for dairy beverage producers worldwide:

Leading Asian Dairy Producer

This leading Asian dairy producer implemented Newamstar’s aseptic technology to expand their premium milk product line beyond regional distribution limitations. The system enabled them to achieve a 9-month ambient shelf life while maintaining fresh milk sensory characteristics, as confirmed by extensive consumer testing. Production efficiency improvements of 28% resulted from extended run times between cleaning cycles, while distribution costs decreased by 35% through elimination of cold chain requirements. Within 18 months of implementation, the company expanded distribution to five new regional markets previously inaccessible due to cold chain limitations.

European Premium Dairy Brand

A premium European dairy brand specializing in protein-enhanced fitness beverages implemented Newamstar’s aseptic system to address persistent challenges with protein stability and sedimentation in their existing production system. The new technology enabled them to achieve a 12-month ambient shelf life with zero quality-related returns or recalls since implementation. Energy consumption decreased by 42% compared to their previous system through advanced heat recovery systems. The enhanced product quality and extended shelf life contributed to a 24% market share increase within the first year, establishing the brand as the category leader in the functional dairy beverage segment.

Nutritional Enhancement Through Advanced Processing

Beyond preservation, Newamstar’s dairy aseptic technology enables enhanced nutritional profiles that satisfy growing consumer demand for functional dairy products:

Protein Preservation

Specialized processing maintaining protein bioavailability with optimized thermal profiles preserving whey protein structures, minimal denaturation ensuring maximum nutritional value in high-protein dairy formulations, and verified protein functionality throughout shelf life through specialized testing protocols.

Vitamin Retention

Advanced processing preserving heat-sensitive vitamins with minimal thermal impact on vitamin B complex, specialized handling maintaining vitamin A and D stability throughout shelf life in fortified products, and oxygen management preventing degradation of sensitive nutrients during processing and storage.

Probiotic Compatibility

Post-process inoculation capabilities for live culture products with aseptic addition of probiotic strains after thermal processing, specialized handling maintaining culture viability throughout distribution and shelf life, and verified probiotic survival rates exceeding industry standards throughout product shelf life.

Functional Ingredient Integration

Specialized handling for heat-sensitive functional ingredients with optimized processing for omega-3 fatty acids, plant sterols, and bioactive peptides, uniform distribution ensuring consistent dosing and efficacy throughout product shelf life, and verified functional component stability throughout the extended shelf life period.

Packaging Innovation for Dairy Products

Newamstar’s aseptic technology enables innovative packaging solutions that enhance consumer appeal while maintaining product integrity:

Advanced Barrier Technologies

Specialized packaging materials protecting dairy product sensitivity to light and oxygen with multi-layer structure optimization for dairy-specific needs, advanced barrier properties preserving vitamin content and preventing oxidation throughout shelf life, and verified flavor protection through accelerated sensory testing protocols.

On-the-Go Format Capability

Specialized filling systems compatible with single-serve and portion-controlled containers with precise filling of challenging formats like pouches and mini-bottles, advanced cap/closure systems ensuring product integrity for portable consumption, and integrated solutions for straws and resealable features for convenient consumption.

Sustainable Packaging Support

Compatibility with recyclable and renewable packaging materials with filling system adaptability for lightweighted containers, specialized handling for alternative packaging materials like paper-based or biopolymer solutions, and emissions reductions of 25-40% through sustainable packaging integration.

Premium Presentation

Specialized filling technologies supporting unique container designs with filling capabilities for ergonomic and distinctive shapes, precision filling ensuring optimal product presentation in transparent containers for premium product positioning, and compatibility with metallized and specialized finishing options enhancing shelf presence.

Regulatory Compliance and Validation

Dairy products face intense regulatory scrutiny worldwide. Newamstar’s systems incorporate comprehensive validation and compliance features:

Comprehensive Regulatory Support

- Process Validation: Comprehensive thermal distribution studies with temperature mapping throughout processing system, biologicals validation proving consistent microbial reduction, and validation protocols meeting PMO, EU, and international dairy standards

- HACCP Integration: Identified Critical Control Points with automated monitoring and control systems, integrated record-keeping for regulatory documentation, and verification procedures ensuring ongoing compliance with established parameters

- Traceability Systems: Complete batch tracking capabilities with integrated coding and traceability features, electronic record systems compliant with FDA 21 CFR Part 11, and full material and process chain documentation for each production lot

- Global Standards Compliance: Design and validation meeting ISO, 3-A Sanitary, EHEDG, and FDA requirements with international regulatory support documentation and pre-validated system designs accepted by major global dairy regulatory authorities

- Quality Assurance: Inline quality verification with integrated monitoring systems, automated rejection of non-conforming products ensuring consistent compliance, and comprehensive testing protocols verifying finished product safety and quality

The Economic Impact: ROI Analysis for Dairy Producers

Beyond technical benefits, Newamstar’s systems deliver compelling financial returns for dairy beverage manufacturers:

Supply Chain Transformation

Elimination of cold chain requirements reducing distribution costs by 30-45% with ambient warehousing reducing storage expenses, extended shelf life decreasing obsolescence and returns by 25-35%, and dramatic expansion of potential distribution network without refrigeration infrastructure constraints.

Operational Efficiency Gains

Production efficiency improvements of 25-40% through extended run times with utility consumption reductions of 30-45% compared to conventional systems, labor efficiency improvements through automation and reduced changeover times, and decreased maintenance requirements through specialized dairy-optimized components.

Market Expansion Opportunities

Geographical market expansion without cold chain infrastructure with export capabilities to previously inaccessible markets, distribution channel diversification beyond refrigerated retail environments creating new revenue streams, and penetration into institutional and food service segments requiring extended shelf life dairy options.

Typical ROI Analysis

Comprehensive financial modeling showing typical ROI period of 24-36 months with detailed cost-benefit analysis including operational savings, market expansion benefits, and sustainability improvements, plus documented case studies demonstrating actual financial outcomes across diverse dairy operations and product portfolios.

Future Innovations: Next-Generation Dairy Processing

Newamstar continues to develop advanced technologies specifically enhancing dairy production capabilities:

Advanced Protein Protection

Next-generation thermal technologies with enhanced protein stability monitoring, optimized heating profiles extending shelf life without protein degradation, innovative heat exchange surfaces virtually eliminating protein denaturation during processing, and real-time protein quality verification through advanced analytics.

Alternative Sterilization Methods

Integration of non-thermal sterilization technologies including high-pressure processing, pulsed electric field, and advanced filtration options, providing enhanced sensory quality with equivalent safety assurance levels for heat-sensitive dairy formulations, and reduced energy consumption profiles supporting sustainability objectives.

AI-Enhanced Quality Management

Advanced real-time monitoring with artificial intelligence identifying subtle quality deviations before they become issues, predictive maintenance algorithms preventing unplanned downtime, automated processing adjustments optimizing product quality based on input variations, and machine learning systems continuously improving processing parameters based on quality outcomes.

Enhanced Sustainability Technology

Next-generation water and energy recovery systems with reduced carbon footprint processing capabilities, enhanced CIP systems reducing chemical and water usage by up to 50%, and innovative waste stream valorization technologies creating valuable by-products from processing waste streams.

Implementation Partnership: Beyond Equipment Supply

Newamstar’s approach goes beyond equipment provision to deliver comprehensive implementation support ensuring optimal results:

Customized Solution Development

Collaborative process design based on specific dairy product requirements with detailed product and process analysis identifying optimal solutions and comprehensive feasibility studies evaluating technical and economic factors before implementation begins.

Implementation Excellence

Comprehensive project management ensuring smooth integration with existing operations, specialized installation teams with dairy industry expertise, and phased implementation approaches minimizing production disruption during transition.

Process Optimization

Post-implementation parameter tuning achieving optimal product quality and efficiency with comprehensive production staff training programs and ongoing technical support ensuring sustained performance excellence throughout system lifespan.

Lifecycle Partnership

Long-term partnership approach with scheduled maintenance and upgrade programs, performance monitoring and continuous improvement initiatives, and technology refreshment strategies ensuring systems remain at the forefront of dairy processing technology.

Environmental Leadership Through Innovation

Newamstar’s aseptic filling technology represents more than merely an operational solution—it embodies a comprehensive approach to environmental sustainability in beverage manufacturing. By simultaneously addressing multiple environmental dimensions—energy, water, waste, packaging, and lifecycle impacts—these systems deliver meaningful progress toward sustainability objectives.

For beverage manufacturers navigating increasingly stringent environmental regulations, growing consumer environmental consciousness, and corporate sustainability commitments, Newamstar’s technology offers a powerful tool for environmental improvement. The documented results across diverse implementations demonstrate that environmental benefits need not come at the expense of operational performance or product quality—indeed, properly implemented aseptic technology enhances all these dimensions simultaneously.

“As the beverage industry continues its sustainability journey, Newamstar’s commitment to continuous environmental innovation ensures that its aseptic filling technology will remain at the forefront of environmentally responsible manufacturing solutions. For forward-thinking beverage producers, this technology represents not merely a production solution but a strategic asset in building a more sustainable future for the industry.”

Global Impact and Industry Recognition

Throughout its evolutionary journey, Newamstar has successfully delivered over 2,300 production lines to customers across more than 100 countries and regions worldwide. The company’s aseptic filling technology has been embraced by international beverage giants including Coca-Cola, PepsiCo, Danone, and Nestlé, as well as leading domestic brands like Master Kong, Wahaha, and Nongfu Spring.

As a testament to its technical excellence, Newamstar has received numerous industry accolades and holds over 500 invention patents, many specifically related to aseptic filling innovations. This recognition reflects not only the company’s technological capabilities but also its commitment to driving industry advancement.

Key Achievements in Aseptic Filling Technology

Transform Your Dairy Production with Newamstar

Discover how Newamstar’s specialized dairy aseptic technology can help you achieve exceptional product quality, extended shelf life, and operational excellence for your premium dairy beverage products.