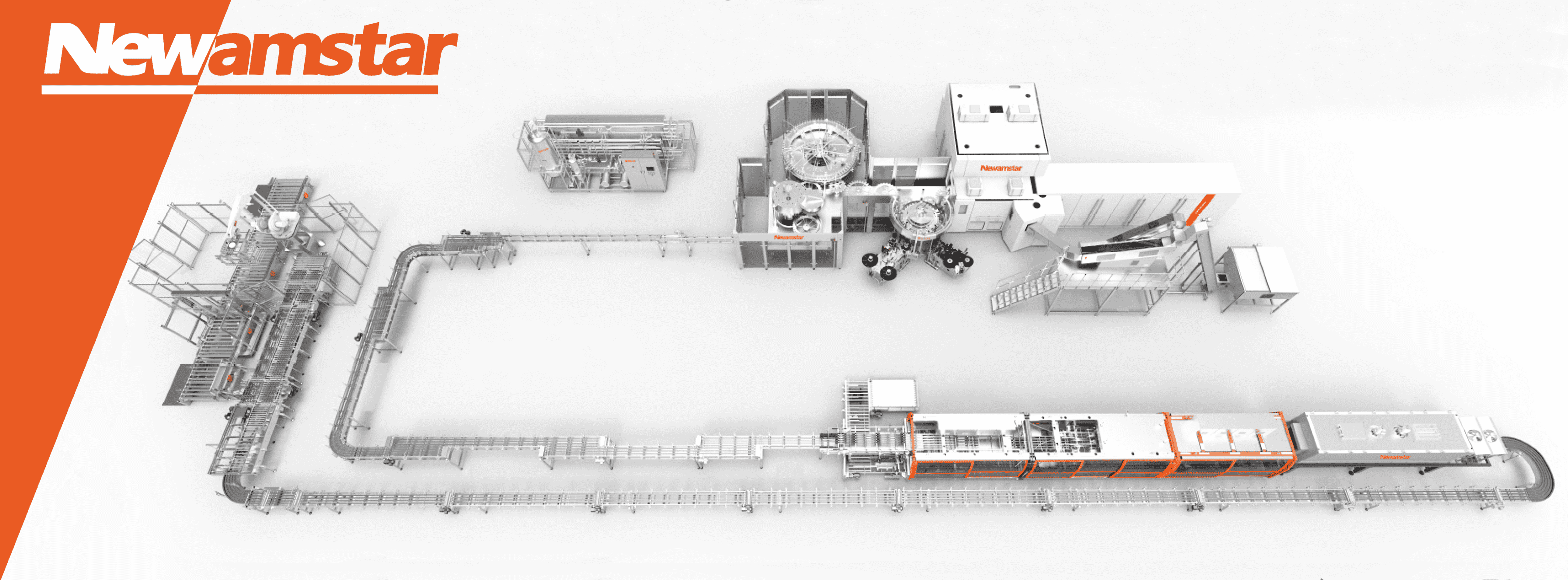

Advanced Aseptic PET Bottle Packaging Solution System

Newamstar’s advanced aseptic filling technology delivers unparalleled performance in sterile beverage packaging. Our integrated blow-fill-cap systems combine cutting-edge electron beam, hydrogen peroxide, and PAA sterilization methods to ensure product safety and extended shelf life without preservatives. With production capacities from 12,000 to 108,000 bottles per hour and compatibility with various beverage types including dairy, juice, and tea, Newamstar’s aseptic filling machines represent the pinnacle of efficiency, reliability, and innovation in liquid packaging solutions.

Product Description

Redefining Efficiency With Integrated Packaging Solutions

Integrated Blow-Fill-Cap

Technology

Advanced Smart Control

Interface System

Efficient Production Flow

Management Design

Comprehensive Quality

Validation Process

Newamstar’s advanced aseptic filling technology represents the pinnacle of beverage packaging innovation, designed to meet the most demanding requirements for product safety, quality preservation, and production efficiency. Founded in 1986, Newamstar is China’s most historic and technologically advanced equipment supplier in the industry. Our systems deliver uncompromising performance for manufacturers seeking extended shelf-life products without preservatives.

Years of Innovation

Production Lines Delivered

Countries with Installations

Key Features & Benefits

Complete Integration

Our BFC Combiblock combines blow molding, filling, and capping in one seamless system

Advanced Sterilization

Multiple sterilization technologies including PAA wet sterilization, hydrogen peroxide dry sterilization, and electron beam sterilization

Extended Shelf-Life

Ensures product preservation without refrigeration for up to 12 months

High Production Capacity

Available in configurations from 12,000 to 108,000 bottles per hour

Reduced Footprint

Up to 40% space savings compared to conventional separated systems

Smart Monitoring

Real-time production data and intelligent control systems

Aseptic Technology Overview

Aseptic filling technology is a sophisticated process that enables the packaging of commercially sterile products into sterile containers within a sterile environment. This technology revolutionizes beverage production by extending shelf life without requiring refrigeration or preservatives.

How Newamstar’s Aseptic Technology Works

Preform Sterilization

PET preforms undergo thorough sterilization before entering the blow molding stage

Sterile Environment

The entire production process occurs within a controlled cleanroom environment with HEPA-filtered air

Integrated Blow Molding

Sterilized preforms are blown into bottles within the aseptic zone, eliminating contamination risks

Precision Filling

Products are filled using non-contact filling valves with laminar flow protection

Cap Sterilization

Caps undergo separate sterilization processes before application

Hermetic Sealing

The filled bottles are immediately sealed to maintain sterility

Newamstar’s Complete Innovation Journey

For nearly four decades, Newamstar has pioneered revolutionary advancements in beverage packaging technology. From our humble beginnings as Sanxing Sheet Metal Factory in 1986 to becoming a global leader in integrated packaging solutions, our history reflects our unwavering commitment to innovation and excellence.

Application Areas

Newamstar’s aseptic filling systems are designed to handle a wide range of beverage products, delivering extended shelf-life without preservatives or refrigeration.

High-Acid Products (pH below 4.6)

- Fruit juices and nectars

- Sports and energy drinks

- Flavored water

- Tea-based beverages

- Carbonated soft drinks

- Coconut water

Low-Acid Products (pH above 4.6)

- Dairy milk and flavored milk

- Plant-based milk alternatives (soy, almond, oat)

- Protein drinks

- Coffee beverages

- Nutritional drinks

- Meal replacement beverages

Advanced Sterilization Technologies

As the only supplier in Asia that masters all three major sterilization technologies, Newamstar offers multiple options to match specific product requirements.

PAA (Peracetic Acid) Wet Sterilization

- Process: Preforms and caps are treated with a precisely controlled PAA solution

- Advantages: Well-established technology with proven effectiveness

- Best for: High-acid products with standard production requirements

- Capacity range: 12,000 – 36,000 bottles per hour

Hydrogen Peroxide Dry Sterilization

- Process: Vaporized hydrogen peroxide is applied followed by hot air activation

- Advantages: No water consumption, reduced chemical usage

- Best for: Wide range of products including low-acid beverages

- Capacity range: 12,000 – 72,000 bottles per hour

Electron Beam (E-beam) Sterilization

- Process: High-energy electrons sterilize packaging materials without chemicals

- Advantages: Chemical-free process, highest environmental performance

- Best for: Premium products and high-speed production

- Capacity range: 36,000 – 108,000 bottles per hour

Production Advantages

Operational Efficiency

- Reduced production steps through integration

- Minimized product loss during changeovers

- Lower energy consumption compared to conventional lines

- Reduced labor requirements through automation

- Simplified maintenance procedures

Quality Assurance

- Consistent microbiological safety

- Extended product shelf-life without preservatives

- Enhanced flavor preservation

- Maintained nutritional value

- Continuous quality monitoring systems

Flexibility & Adaptability

-

-

- Multiple product capabilities on the same line

- Various packaging size options

- Quick changeover systems

- Modular design for future upgrades

- Compatibility with different bottle designs

-

Complete Aseptic Production Line Solutions

Beyond the core aseptic filling technology, Newamstar provides comprehensive production line solutions that integrate every aspect of the beverage manufacturing process.

Upstream Systems

- Water Treatment Systems: Multiple filtration stages, UV sterilization, and reverse osmosis

- Syrup Preparation Units: Sugar dissolution, pasteurization, and ingredient mixing

- UHT Treatment Systems: Direct and indirect heating options for product sterilization

- Homogenizers: High-pressure homogenization for consistent product texture

- Buffer Tanks: Aseptic storage with level control and temperature maintenance

Downstream Systems

- Labeling Systems: Integrated OPP, paper, or sleeve labeling options

- Inspection Systems: Weight verification, leak detection, and vision inspection

- Secondary Packaging: Shrink-wrapping, carton packing, and case erecting

- Palletizing Solutions: Robotic or conventional palletizing with stretch wrapping

- Intelligent Warehousing: Automated storage and retrieval systems

Technical Innovations in Aseptic Filling Technology

Newamstar’s continued R&D investment has yielded significant innovations that elevate our aseptic filling systems beyond conventional technologies. These advancements deliver tangible benefits for beverage manufacturers seeking the highest standards in product safety and operational efficiency.

Advanced Laminar Flow Protection

Our proprietary laminar airflow system creates a sterile curtain around the filling zone, maintaining a Grade A environment precisely where it matters most. This targeted approach reduces the overall cleanroom footprint while enhancing sterility assurance levels beyond industry standards.

Non-Contact Filling Technology

Newamstar’s advanced filling valves operate without physical contact with bottle necks, eliminating a critical contamination risk point. The precision-engineered valve design ensures accurate filling volumes while maintaining a hermetic filling environment, even at high production speeds.

Synchronized Servo Control System

Each critical function in our aseptic systems is driven by independent servo motors with synchronized digital control. This approach enables precise timing adjustments, gentle handling of both bottles and product, and significant energy efficiency improvements compared to mechanical transmission systems.

Rapid Changeover Technology

Our patented quick-change components allow format transitions without breaking the sterile barrier, significantly reducing downtime between production runs. Toolless design principles and color-coded components simplify the changeover process, allowing operators to complete transitions in under 30 minutes.

Adaptive Sterilization Control

Intelligent sensors continuously monitor sterilization parameters in real-time, with adaptive algorithms adjusting chemical dosing or irradiation intensity to ensure consistent sterilization effectiveness. This system optimizes chemical and energy usage while providing documented validation of the sterilization process.

Intelligent Control Systems

Newamstar’s aseptic production lines incorporate advanced control systems that ensure precise operation while providing comprehensive production data.

Key Control Features

- Centralized HMI Control: Intuitive touchscreen interface for complete line management

- Real-time Monitoring: Continuous tracking of critical parameters including temperature, pressure, and flow rates

- Production Data Collection: Automated gathering of operational metrics for performance analysis

- Recipe Management: Secure storage and easy retrieval of product formulations and production parameters

- Remote Diagnostics: Online support capabilities for rapid troubleshooting

- Predictive Maintenance: AI-driven analysis to anticipate maintenance needs

- Batch Tracking: Complete traceability from raw materials to finished products

- Industry 4.0 Integration: Compatibility with factory-wide management systems

Quality Assurance & Validation

Newamstar implements comprehensive validation protocols for all aseptic filling systems, ensuring consistent performance and regulatory compliance. Our validation approach follows international standards including FDA, EHEDG, and 3-A Sanitary Standards.

Validation Process

- Design Qualification (DQ): Verification that system design meets user requirements and regulatory standards

- Installation Qualification (IQ): Documented verification that equipment is properly installed according to specifications

- Operational Qualification (OQ): Testing of all operational parameters to ensure they meet predetermined acceptance criteria

- Performance Qualification (PQ): Validation of system performance under actual production conditions

- Cleaning Validation: Verification of CIP effectiveness and residue removal

- Sterilization Validation: Rigorous testing to ensure sterilization effectiveness

Testing Methodologies

- Microbiological Challenge Tests: Verification of system’s ability to eliminate microbiological contamination

- Chemical Residue Analysis: Testing to ensure sterilant removal meets safety standards

- Environmental Monitoring: Continuous assessment of cleanroom conditions

- Media Fills: Simulation of production using growth media to verify aseptic conditions

- Shelf-Life Studies: Accelerated and real-time testing of product stability

Each Newamstar aseptic system is delivered with comprehensive validation documentation, facilitating regulatory approvals and quality audits.

Sustainability in Aseptic Production

Newamstar is committed to developing environmentally responsible manufacturing solutions. Our aseptic filling systems incorporate multiple sustainability features that reduce environmental impact while delivering operational benefits.

Resource Optimization

- Water Conservation: Closed-loop water systems reduce freshwater consumption by up to 30%

- Energy Efficiency: Advanced heat recovery systems capture and reuse thermal energy

- Chemical Reduction: Precision application systems minimize sterilant usage

- Material Efficiency: Lightweight bottle capability reduces plastic consumption

Waste Reduction

- Product Loss Minimization: Precision filling reduces overfill and product waste

- Packaging Optimization: Integrated design eliminates unnecessary packaging materials

- Chemical-Free Options: E-beam technology eliminates chemical sterilants entirely

- Digital Twin Optimization: Virtual commissioning reduces setup waste

Environmental Protection

- Reduced Carbon Footprint: Efficient operations lower overall energy consumption

- Clean Sterilization: Advanced technologies minimize environmental discharges

- Noise Reduction: Acoustic insulation minimizes operational noise

- Extended Equipment Lifecycle: Modular design facilitates upgrades rather than replacement

Digital Capabilities for Industry 4.0

Newamstar’s aseptic systems are designed for seamless integration within Industry 4.0 manufacturing environments, with comprehensive digital features that enhance productivity, quality assurance, and operational intelligence.

Digital Twin Technology

- Pre-implementation simulation and optimization

- Virtual commissioning to reduce startup time

- Operator training in a simulated environment

- Predictive performance analysis

- Virtual testing of production parameters

Advanced Analytics Platform

- Real-time OEE calculation

- Predictive maintenance recommendations

- Product quality correlation analysis

- Energy consumption optimization

- Comparative analysis across batches

Integration Capabilities

- ERP system integration

- MES connectivity for production tracking

- LIMS integration for quality data

- Supply chain management connectivity

- Warehouse management system integration

Remote Services Platform

- Secure remote monitoring capabilities

- Real-time technical support

- Remote software updates

- Performance benchmarking

- Digital documentation access

Comparative Advantages of Newamstar Aseptic Technology

When evaluating aseptic filling options, manufacturers must consider multiple factors that impact total cost of ownership and long-term performance. Newamstar’s integrated solutions offer distinct advantages compared to conventional approaches.

Comprehensive Service & Support

Newamstar provides end-to-end support for our aseptic filling systems, ensuring optimal performance throughout the equipment lifecycle.

Pre-Installation Services

- Factory layout design and optimization

- Utility requirements planning

- Production flow analysis

- Capacity planning consultation

- ROI analysis assistance

Implementation Services

- Professional installation supervision

- Comprehensive system commissioning

- Validation protocol execution

- Operator training programs

- Production start-up support

Ongoing Support

- 24/7 technical assistance

- Preventive maintenance programs

- Spare parts management

- Software updates and upgrades

- Performance optimization services

Comprehensive Training Programs

The successful operation of aseptic filling systems requires specialized knowledge and skills. Newamstar offers comprehensive training programs tailored to different personnel roles and experience levels.

Operator Training

- Basic Operation: Machine startup, shutdown, and standard procedures

- Production Management: Format changes, routine adjustments, and monitoring

- Quality Control: In-process checks and quality verification procedures

- Troubleshooting: Identifying and resolving common production issues

- Safety Protocols: Proper handling of equipment and materials

Maintenance Training

- Preventive Maintenance: Scheduled service procedures and inspections

- Component Replacement: Proper techniques for parts replacement

- Calibration: Sensor and measuring device adjustment procedures

- Advanced Diagnostics: Using system tools to identify issues

- Spare Parts Management: Inventory planning and critical component identification

Quality Assurance Training

- Aseptic Principles: Fundamental concepts and critical control points

- Microbiological Testing: Sampling techniques and interpretation

- Validation Procedures: Executing and documenting validation protocols

- Environmental Monitoring: Cleanroom monitoring procedures

- Documentation: Record keeping and compliance management

Management Training

- Performance Optimization: Analyzing and improving production metrics

- Resource Planning: Staff and material requirement forecasting

- Regulatory Compliance: Understanding and meeting industry standards

- Cost Control: Identifying and implementing efficiency improvements

- Technology Roadmap: Planning for future upgrades and enhancements

Success Stories

With over 2,300 production lines delivered globally and more than 100 aseptic installations, Newamstar has established a proven track record of excellence in beverage packaging technology.

Major Dairy Producer

A leading Asian dairy manufacturer implemented Newamstar’s 36,000 BPH aseptic filling line for flavored milk products, achieving a 30% increase in production capacity while reducing operational costs by 15%. The integrated system allowed the customer to launch innovative new products with extended shelf-life, significantly expanding their market reach.

Premium Juice Processor

A premium juice company upgraded to Newamstar’s electron beam sterilization technology, eliminating chemical usage in their production process. This improvement supported their clean-label marketing strategy and enhanced their sustainability profile, resulting in increased market share in the premium beverage segment.

Global Beverage Corporation

After implementing multiple Newamstar aseptic lines across their global manufacturing network, this international beverage leader standardized on our technology for all new aseptic installations. The reliability and consistent performance of our systems helped them achieve their ambitious production efficiency targets while maintaining the highest quality standards.

The Evolution of Aseptic Filling Technology

The development of aseptic filling technology represents one of the most significant advancements in food preservation history. Newamstar has played a pivotal role in this evolution, particularly in the Asian market, helping to establish new standards for beverage safety and quality.

Historical Context & Future Development

First Generation (1950s-1970s)

Early aseptic systems focused on sterilizing containers using heat and chemicals, with limited production speeds and significant operational complexity. These systems primarily served the dairy industry for milk and cream products.

Second Generation (1980s-1990s)

Improvements in sterilization technology and automation expanded capabilities to include juice and other non-dairy beverages. Production speeds increased, though systems remained separate with blow molding, filling, and capping as discrete operations.

Third Generation (2000s-2010s)

The introduction of integrated blow-fill-cap technology represented a significant leap forward, with Newamstar pioneering this approach in China starting in 1999. These systems dramatically improved efficiency and product safety while expanding the range of products suitable for aseptic packaging.

Current Generation (2010s-Present)

Today’s advanced aseptic systems incorporate digital control systems, enhanced sterilization technologies, and comprehensive validation capabilities. Newamstar’s leadership in electron beam sterilization and high-speed production represents the cutting edge of this technology evolution.

Future Development

Newamstar continues to drive aseptic technology forward with research into fully autonomous production systems, enhanced sustainability features, and expanded material compatibility. Our R&D investments focus on anticipating industry needs and delivering solutions that address emerging challenges.

Preform

Blow Molding

Filling

Capping

Labeling

Packaging

Frequently Asked Questions

What types of beverages can be processed on Newamstar’s aseptic filling lines?

Newamstar’s aseptic filling systems can process a wide range of beverages including water, juices, teas, dairy products, plant-based milks, protein drinks, sports beverages, and other liquid food products. Our systems are designed to handle both high-acid (pH below 4.6) and low-acid (pH above 4.6) products.

What is the shelf life of products filled on Newamstar’s aseptic systems?

Products filled on our aseptic systems typically achieve shelf lives of 6-12 months without refrigeration, depending on the specific product characteristics and packaging materials used. Some products can achieve even longer shelf life with appropriate formulation and packaging.

What bottle sizes can be handled on Newamstar’s aseptic filling lines?

Our aseptic systems can handle PET bottles ranging from 250ml to 2.0L, with specific capacity ranges varying by system configuration. Custom solutions for other sizes may be available upon consultation.

How does Newamstar ensure the sterility of the packaging process?

Newamstar employs multiple sterilization technologies including PAA wet sterilization, hydrogen peroxide dry sterilization, and electron beam sterilization. The entire process occurs within a controlled cleanroom environment with HEPA-filtered air, positive pressure, and continuous monitoring of critical control points.

What is the typical installation time for an aseptic filling line?

Installation time varies depending on line complexity and capacity, but typically ranges from 3-6 months from equipment delivery to production qualification. Our experienced project management team works closely with customers to minimize downtime and ensure smooth implementation.

Does Newamstar provide training for operating personnel?

Yes, comprehensive training programs are included with all Newamstar aseptic systems. Training covers operation, maintenance, troubleshooting, and quality control procedures. Both on-site and factory training options are available.

Ready to Elevate Your Beverage Production?

Contact our aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can transform your beverage manufacturing capabilities.

Global Aseptic Technology Presence

With over 2,300 liquid product production lines successfully implemented across more than 100 countries and regions globally, Newamstar has established a worldwide footprint of excellence. Our technology adaptability ensures optimal performance across diverse operating environments, climate conditions, and regulatory frameworks.

Regional Solution Adaptations

- Tropical Climate Solutions: Enhanced environmental control systems for high-humidity regions

- High-Altitude Installations: Specialized pressure control systems for elevated locations

- Cold Climate Implementations: Thermal protection systems for low-temperature environments

- Challenging Water Quality Regions: Enhanced water treatment capabilities

Global Regulatory Compliance

- FDA (Food and Drug Administration) requirements

- EHEDG (European Hygienic Engineering & Design Group) guidelines

- 3-A Sanitary Standards

- China NMPA regulations

- FSSC 22000 food safety management system requirements

- ISO 14159 (Hygiene requirements for machinery design)

Global Aseptic Solutions Provider

Aseptic Installations

Production Lines

Countries & Regions

Sterilization Technologies

From fruit juices to dairy products, and from tea beverages to plant-based alternatives, Newamstar has successfully implemented aseptic solutions across a diverse range of applications worldwide.

Our expertise spans the full spectrum of liquid product categories, with tailored solutions that address the unique challenges of each product type while maintaining the highest standards of quality and safety.

Complete Aseptic Production Ecosystem

Maximize your investment with Newamstar’s comprehensive aseptic production ecosystem. Our integrated solutions work in perfect harmony to deliver exceptional efficiency, product quality, and operational excellence.

Transform Your Beverage Production

Contact our aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can elevate your manufacturing capabilities.