Product Description

Production Lines Delivered

Countries with Installations

Coconut Water Preservation Expert

Our specialized low-shear filling technology and advanced anti-oxidation systems ensure maximum retention of delicate coconut water nutrients and authentic flavor profiles throughout the filling process.

- 95% natural enzyme retention

- Superior preservation of electrolytes & minerals

- Authentic tropical flavor profile maintenance

Coconut-Specific Intelligent Control

Intuitive operator interfaces with advanced monitoring capabilities tailored for coconut water’s unique processing challenges, ensuring consistent quality and extended shelf life without preservatives.

- Real-time crystallization prevention monitoring

- Predictive maintenance notifications

- Specialized pH stability control systems

Coconut Water Production Process

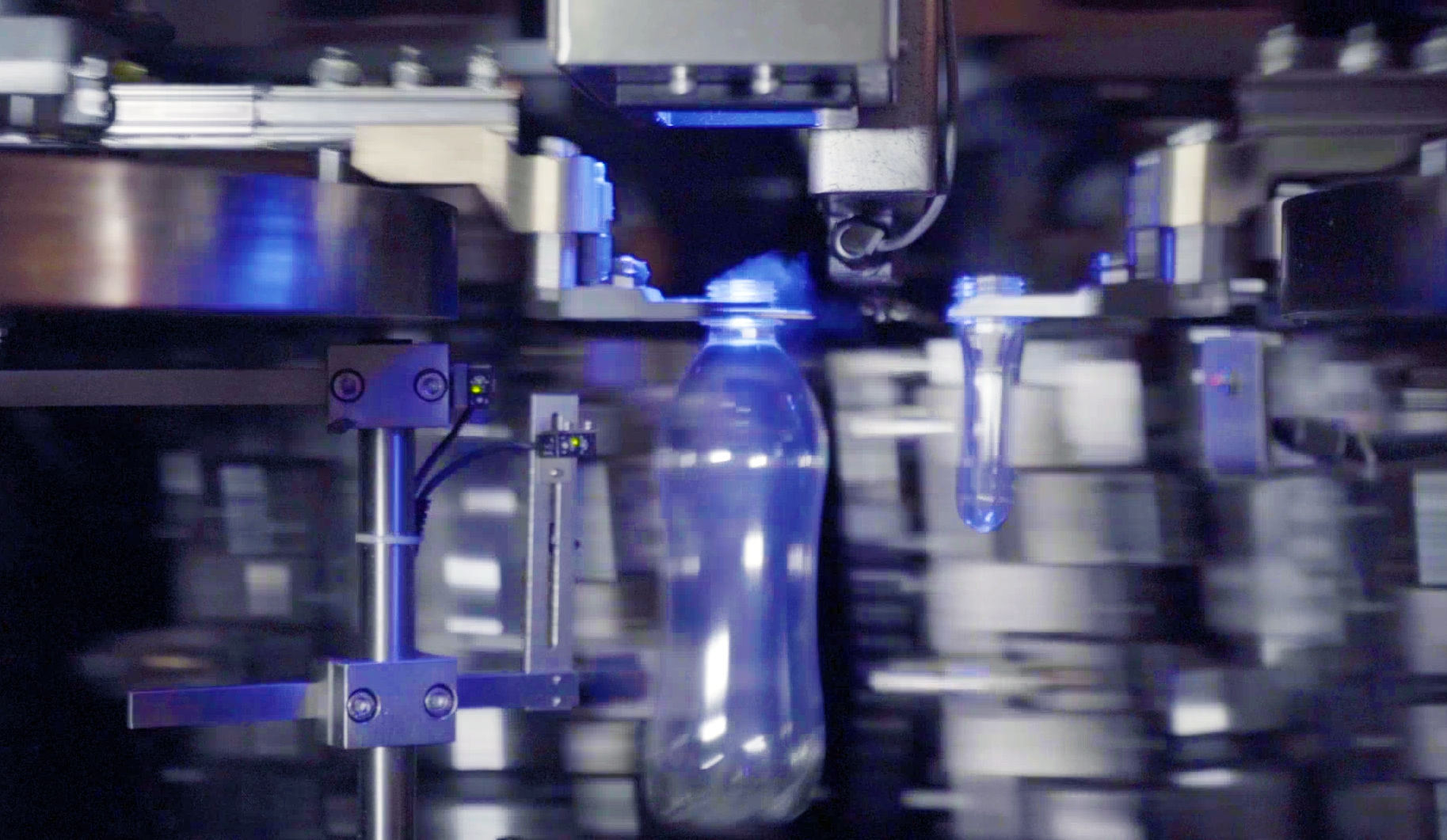

Sterile Preform Processing

PET preforms are molded into bottles in a strictly controlled ultra-clean environment, ensuring complete sterility for coconut water’s sensitive nature

Coconut-Optimized Filling

Our specialized low-turbulence filling valves preserve delicate coconut water components while preventing oxidation and ensuring precise fill levels

Nitrogen Injection & Sealing

Nitrogen flush technology and advanced capping creates the perfect anaerobic environment to maintain coconut water’s delicate flavor profile and nutrient content

Advanced Quality Verification

Specialized inspection systems for coconut water verify product clarity, fill levels, cap integrity, and package integrity to ensure 12+ month ambient shelf life

Why Choose Newamstar for Coconut Water

Our coconut water-specific filling systems exceed traditional technology in multiple key areas, providing significant competitive advantages for this challenging beverage

Customer Success Stories

Discover how Newamstar’s liquid product filling solutions are transforming production efficiency worldwide

Specialized Coconut Water Processing Technologies

Newamstar has developed dedicated processing technologies optimized for coconut water’s unique characteristics, ensuring both product safety and maximum retention of its natural properties.

Anti-Browning Technology

- Process: Proprietary oxygen displacement and anti-oxidant management system

- Advantages: Prevents enzymatic browning, maintains natural clarity

- Best for: Pure coconut water and coconut water blends

- Result: Crystal clear product throughout extended shelf life

Coconut Particulate Management

- Process: Advanced flow dynamics preventing settling or clogging

- Advantages: Consistent coconut pulp distribution when desired

- Best for: Natural coconut water with pulp inclusion

- Result: Perfectly consistent product quality bottle-to-bottle

Enhanced CIP/SIP Systems

- Process: Specialized cleaning protocols for coconut mineral deposits

- Advantages: Superior removal of coconut residues between runs

- Best for: Production facilities with multiple SKUs

- Result: Reduced downtime and extended equipment life

Frequently Asked Questions

What challenges does coconut water present for aseptic filling?

Coconut water presents several unique challenges including high sensitivity to oxidation, natural enzymes that can cause browning, varying mineral content that can form deposits, and occasional coconut pulp particles. Our specialized systems address each of these challenges through a combination of gentle handling, oxygen management, specialized valve designs, and enhanced cleaning protocols.

How does Newamstar’s technology prevent coconut water browning?

Our systems employ a comprehensive anti-browning strategy including minimal oxygen exposure during processing, nitrogen flushing before sealing, specialized non-metal contact components, and ultra-gentle handling that minimizes enzyme activation. The result is coconut water that maintains its natural clarity and appearance throughout shelf life without requiring additives or preservatives.

Can Newamstar’s systems handle both clear and pulp-inclusive coconut water?

Yes, our systems are specifically designed to handle both clear coconut water and varieties containing pulp or particulates. Our specialized valves and flow paths maintain gentle handling while preventing clogging or uneven distribution of coconut pulp particles. The system can be rapidly configured to switch between different product formulations with minimal downtime.

What bottle sizes are available for coconut water packaging?

Our coconut water aseptic systems can handle PET bottles ranging from 200ml to 2.0L, with specific capacity ranges varying by system configuration. The most popular sizes for coconut water products are 330ml, 500ml, and 1L formats, all of which run efficiently on our systems. Custom bottle shapes optimized for coconut water branding are also available through our design services.

Newamstar’s Complete Innovation Journey

For nearly four decades, Newamstar has pioneered revolutionary advancements in beverage packaging technology. From our humble beginnings as Sanxing Sheet Metal Factory in 1986 to becoming a global leader in integrated packaging solutions, our history reflects our unwavering commitment to innovation and excellence.

Production Capacity Options

Newamstar’s coconut water aseptic filling systems are available in multiple configurations to meet your specific production volume requirements.

Small to Medium Scale

- Production rate: 12,000 – 24,000 bottles per hour

- Footprint: Compact design from 400m²

- Features: Quick changeover capability

- Best for: Regional brands, product launches

- Configuration: Single or dual-lane options

Large Scale Production

- Production rate: 36,000 – 48,000 bottles per hour

- Footprint: Optimized layout from 600m²

- Features: Advanced automation, remote monitoring

- Best for: National distribution, export markets

- Configuration: Multi-lane high-efficiency design

Global Coconut Water Production Solutions

Coconut Water Installations

Total Production Lines

Tropical Countries Served

Specialized Technologies

From Thailand to Brazil, and from the Philippines to global export markets, Newamstar has implemented coconut water processing solutions worldwide, adapting to local product characteristics and environmental conditions.

Our expertise spans all coconut water varieties, with tailored solutions that address the unique challenges of each geographic source, processing need, and brand requirement while maintaining the highest standards of tropical authenticity and product safety.

Complete Coconut Water Processing Ecosystem

Maximize your investment with Newamstar’s comprehensive coconut water ecosystem. Our integrated solutions work in perfect harmony from processing to packaging, delivering exceptional efficiency, product quality, and operational excellence for this challenging tropical beverage.

Transform Your Coconut Water Production

Contact our coconut water aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s specialized filling systems can elevate your tropical beverage manufacturing capabilities.