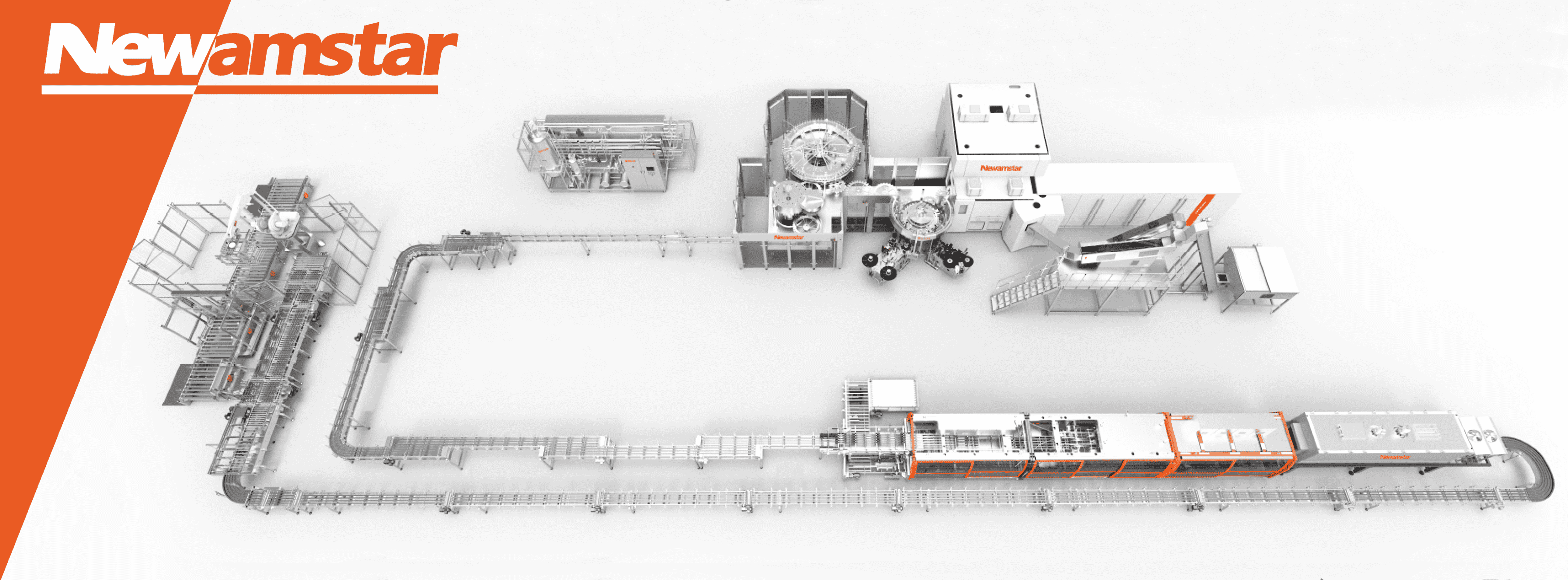

Newamstar Fruit & Vegetable Juice Aseptic Filling Production Line

Newamstar’s Fruit & Vegetable Juice Aseptic Filling Line preserves essential nutrients and delicate flavors through specialized pulp-handling technology and minimal oxidation. Our systems ensure 6-12 months shelf stability without preservatives while maintaining maximum nutritional integrity for health-conscious consumers.

Product Description

Advanced Fruit & Vegetable Juice Aseptic Technology – Preserving Natural Nutrition

Precision Filling

Technology

Intelligent Control

Interface

Complete Production

Solution

Comprehensive Quality

System

Newamstar’s advanced fruit and vegetable juice aseptic filling technology represents the pinnacle of sensitive beverage preservation. Engineered specifically to protect heat-sensitive vitamins, antioxidants, and natural flavors, our systems ensure maximum nutritional integrity while delivering extended shelf life without preservatives. From pure fruit juices to vegetable blends and functional beverages, our precision technology preserves both sensory quality and nutritional value that today’s health-conscious consumers demand.

Years of Innovation

Production Lines Delivered

Countries with Installations

Key Features & Benefits

Nutrient Preservation

Advanced low-temperature processing technology preserves heat-sensitive vitamins, enzymes, and antioxidants in fruit and vegetable juices

Pulp Handling Excellence

Specialized filling valves and low-shear pumping systems maintain pulp integrity and ensure consistent particle distribution

Extended Shelf-Life

Guarantees 6-12 months shelf stability for fruit juices without refrigeration or preservatives, maintaining fresh flavor profiles

Clean Label Production

Supports all-natural, preservative-free juice formulations while ensuring complete microbiological safety

Flexible Capacity

Available in configurations from 12,000 to 72,000 bottles per hour to suit production requirements from craft juiceries to industrial scale

Color & Flavor Protection

Minimal oxygen exposure and UV protection systems preserve natural colors and delicate flavor compounds

Juice-Specific Aseptic Technology

Fruit and vegetable juices present unique challenges in aseptic processing due to their high nutritional sensitivity, varying viscosities, and often significant pulp content. Newamstar’s juice-specific aseptic systems incorporate specialized features designed explicitly for these demanding products.

The Juice Processing Advantage

Gentle Product Handling

Low-shear pumping and transfer systems preserve delicate cellular structures in fruit and vegetable juices

Pulp Management System

Specialized agitation and uniform distribution technology ensures consistent pulp levels throughout production

Anti-Oxidation Protection

Advanced nitrogen dosing and minimal oxygen exposure preserve vitamin content and prevent color degradation

Low-Temperature Processing

Optimized thermal profiles minimize heat exposure while ensuring complete microbial inactivation

Viscosity Flexibility

Adaptable filling systems handle products from clear juices to thick smoothies with consistent accuracy

Specialized CIP/SIP

Enhanced cleaning protocols designed for pulp residues and high-sugar products ensure complete sanitation

Production Process

Preform

Blow Molding

Filling

Capping

Labeling

Packaging

Juice Applications

Newamstar’s fruit and vegetable juice aseptic filling systems are engineered to handle the complete spectrum of juice formulations, delivering exceptional product quality and extended shelf life across all variants.

Fruit-Based Beverages

- Clear fruit juices

- Pulpy fruit juices

- Fruit nectars

- Fruit juice blends

- Cold-pressed juices

- Premium 100% juices

Vegetable & Mixed Formulations

- Vegetable juices

- Green blends

- Mixed fruit-vegetable juices

- Carrot-based beverages

- Tomato juice products

- Functional vegetable drinks

Juice-Specific Sterilization Technologies

Newamstar has developed specialized sterilization technologies optimized for juice applications, ensuring both product safety and maximum preservation of nutritional components.

Hydrogen Peroxide Dry Sterilization

- Process: Vaporized hydrogen peroxide application with precise temperature control

- Advantages: Zero water usage, minimal impact on juice quality and nutrient content

- Best for: Premium juices and vitamin-enhanced beverages

- Capacity range: 24,000 – 48,000 bottles per hour

Electron Beam (E-beam) Sterilization

- Process: High-energy electrons sterilize packaging without chemicals or heat

- Advantages: Chemical-free process, highest environmental performance, ideal for organic juices

- Best for: Premium organic and biodynamic juice products

- Capacity range: 36,000 – 72,000 bottles per hour

Advanced PAA Sterilization

- Process: Low-concentration peracetic acid with enhanced rinsing systems

- Advantages: Reliable sterilization with long-established track record for juice applications

- Best for: Standard juice products and high-volume production

- Capacity range: 12,000 – 36,000 bottles per hour

Newamstar’s Complete Innovation Journey

For nearly four decades, Newamstar has pioneered revolutionary advancements in beverage packaging technology. From our humble beginnings as Sanxing Sheet Metal Factory in 1986 to becoming a global leader in integrated packaging solutions, our history reflects our unwavering commitment to innovation and excellence.

Technical Innovations for Juice Processing

Newamstar’s continued R&D investment has yielded significant innovations that elevate our juice processing systems beyond conventional technologies. These advancements deliver tangible benefits for juice manufacturers seeking the highest standards in product quality and nutritional preservation.

Low-Shear Filling Technology

Our proprietary low-shear filling valves minimize mechanical stress on juice particulates, preserving cellular structures and ensuring pulp integrity throughout the filling process. This technology is particularly valuable for cold-pressed and premium juice products where texture and mouthfeel are critical quality attributes.

Nutrient Preservation System

Our specialized Nutrient Preservation System (NPS) combines advanced thermal control, minimal oxygen exposure, and UV protection to safeguard heat-sensitive vitamins, enzymes, and antioxidants throughout the filling process. Independent testing confirms up to 30% higher vitamin retention compared to conventional aseptic systems.

Pulp Distribution Control

Our patented Pulp Distribution Control (PDC) technology employs precision agitation systems and specialized flow dynamics to maintain consistent pulp distribution throughout production runs. This eliminates pulp settling and ensures uniform product quality from the first bottle to the last, even during extended production cycles.

Advanced Quality Control Systems

Fruit and vegetable juices demand exceptional quality control measures to ensure both safety and nutritional value. Newamstar’s integrated quality control systems provide comprehensive monitoring throughout the production process.

In-Line Nutrient Monitoring

- Vitamin Content: Real-time monitoring of key vitamin levels through specialized NIR sensors

- Antioxidant Analysis: Continuous measurement of total antioxidant capacity

- Data Logging: Comprehensive record-keeping for quality verification and traceability

- Trend Analysis: AI-driven prediction of potential nutrient degradation

Critical Control Point Management

- Microbiological Verification: Continuous monitoring of sterilization effectiveness

- Temperature Profiling: Precise thermal control throughout the process

- Oxygen Management: Multi-point measurement of dissolved and headspace oxygen

- Real-time Alerts: Immediate notification of any parameter deviation

Product Consistency Verification

- Pulp Distribution: Optical analysis systems for consistent pulp levels

- Fill-Level Control: High-precision weight and volume verification

- Viscosity Monitoring: Continuous viscosity measurement for consistent mouthfeel

- Color Analysis: Spectrophotometric color verification for visual consistency

Sustainability in Juice Processing

Newamstar is committed to developing environmentally responsible juice manufacturing solutions. Our aseptic filling systems incorporate multiple sustainability features that reduce environmental impact while delivering operational benefits.

Resource Optimization

- Up to 30% reduction in water consumption compared to conventional systems

- Energy recovery systems capture and reuse thermal energy

- Optimized CIP cycles reduce cleaning chemical usage

- Lightweight bottle capability reduces plastic consumption

- Precision filling minimizes product waste

Eco-Friendly Technologies

- Chemical-free electron beam sterilization option

- Low-concentration hydrogen peroxide systems

- Variable speed drives reduce energy consumption

- Heat recovery from sterilization processes

- Biodegradable lubricants in mechanical systems

Sustainability Benefits

- Reduced carbon footprint across the production lifecycle

- Support for environmentally responsible packaging options

- Extended equipment lifecycle through modular design

- Digital twin optimization reduces commissioning waste

- Clean technology certifications available

Comprehensive Service & Support

Newamstar provides end-to-end support for our juice aseptic filling systems, ensuring optimal performance throughout the equipment lifecycle. Our specialized juice processing expertise helps customers achieve the highest levels of product quality and operational efficiency.

Specialized Juice Consulting

- Juice formulation compatibility analysis

- Nutrient retention optimization

- Pulp handling recommendations

- Shelf-life maximization strategies

- Quality control protocol development

Implementation Excellence

- Juice-specific installation supervision

- Comprehensive system commissioning

- Product-specific validation protocols

- Specialized operator training programs

- Production optimization support

Ongoing Technical Support

- 24/7 juice processing technical assistance

- Remote monitoring and diagnostics

- Preventive maintenance programs

- Specialized spare parts management

- Performance enhancement services

Transform Your Juice Production

Contact our juice technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can help you deliver superior juice products with exceptional quality and extended shelf life.

Frequently Asked Questions

What types of juice can be processed on Newamstar’s aseptic filling lines?

Newamstar’s juice aseptic systems can process virtually all fruit and vegetable juice types, including clear juices, pulpy juices, nectars, smoothie-type products, high-pulp formulations, and mixed fruit-vegetable blends. Our systems are designed to handle products with varying viscosities, pulp contents, and pH levels.

How does Newamstar’s technology preserve juice nutrients better than conventional systems?

Our systems employ multiple nutrient preservation technologies: minimal thermal impact during processing, advanced oxygen management to prevent oxidation, specialized light protection, gentle product handling that minimizes mechanical stress, and rapid cooling after filling. Independent testing shows up to 35% higher vitamin retention in juices processed on our systems compared to conventional aseptic lines.

What is the shelf life of juices processed on Newamstar’s systems?

Products filled on our aseptic systems typically achieve shelf lives of 6-12 months without refrigeration, depending on the specific juice formulation and packaging materials used. Products with higher acidity generally achieve longer shelf life. Our technical team can provide specific shelf-life projections based on your exact product specifications.

How does Newamstar handle pulp and particles in juice products?

Our specialized Pulp Distribution Control (PDC) technology employs gentle agitation systems, specialized flow dynamics, and proprietary valve designs to maintain consistent pulp distribution throughout production runs. This eliminates problems with pulp settling and ensures uniform product quality in every bottle. Our systems can handle pulp particles up to 5mm in size without clogging or inconsistent distribution.

Can Newamstar’s systems handle organic juice production?

Yes, our systems are ideal for organic juice production. Our electron beam sterilization technology offers a chemical-free sterilization option that aligns perfectly with organic production principles. Additionally, our low-temperature processing and gentle handling systems help preserve the delicate characteristics of organic ingredients. Many leading organic juice brands worldwide rely on Newamstar technology.