Product Description

Production Lines Delivered

Countries with Installations

Plant Protein Preservation Expert

Our specialized low-shear filling technology and anti-oxidation systems ensure maximum retention of protein structure and nutritional properties throughout the filling process.

- 40% higher protein bioavailability retention

- Minimized protein sedimentation and aggregation

- Exceptional mouthfeel preservation and stability

Intelligent Control Systems

Intuitive operator interfaces with advanced monitoring capabilities ensure perfect production conditions and consistent quality for every plant protein beverage bottle.

- Real-time protein suspension monitoring

- Predictive maintenance notifications

- Comprehensive data logging for quality assurance

Production Process

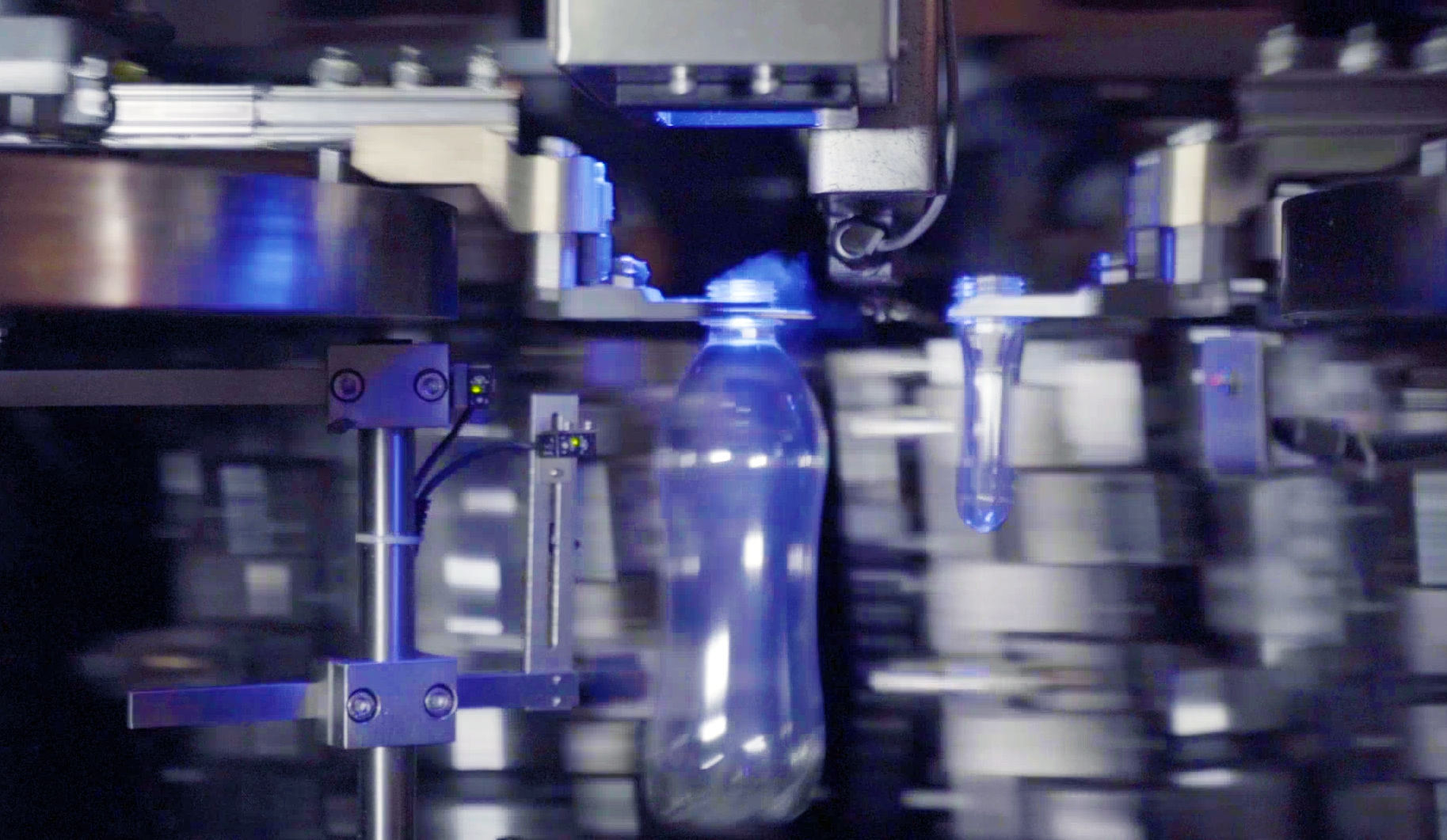

Preform Formation

PET preforms are molded into bottles in a strictly controlled environment, ensuring sterility and consistency of each container for plant protein beverages

Precision Filling

Our specialized anti-foam filling valves preserve delicate plant protein structures while preventing sedimentation and ensuring accurate fill levels

Hermetic Sealing

Advanced capping technology creates a perfect seal to maintain product sterility and prevent oxidation throughout shelf life for optimal plant protein stability

Quality Validation

Comprehensive inspection systems verify every aspect of plant protein product quality, from protein suspension stability to fill levels and cap integrity

Frequently Asked Questions

What types of plant protein beverages can be processed on Newamstar’s aseptic filling lines?

Newamstar’s aseptic filling systems can process all types of plant-based beverages including soy milk, almond milk, oat milk, rice milk, pea protein drinks, and other plant protein formulations. Our systems are specifically designed to handle the unique challenges of plant proteins, such as foaming tendencies and sedimentation issues.

How does Newamstar’s technology prevent protein sedimentation in plant-based beverages?

Our systems employ proprietary fluid dynamics and specialized filling valves designed specifically for plant proteins. The gentle handling process minimizes shear forces that can denature proteins, while our suspension technology maintains uniform distribution throughout the filling process, preventing the sedimentation issues common with conventional filling systems.

What is the shelf life of plant protein products filled on Newamstar’s aseptic systems?

Plant protein beverages filled on our aseptic systems typically achieve shelf lives of 6-12 months without refrigeration, depending on the specific formulation and packaging materials used. Our advanced sterilization methods and anti-oxidation technologies help preserve protein integrity and flavor profiles throughout the extended shelf life.

How does Newamstar address the foaming challenges common with plant protein beverages?

Our systems incorporate specialized anti-foaming filling valves with bottom-up filling technology and controlled flow rates. The filling process is carefully calibrated to minimize turbulence and air incorporation, significantly reducing the foaming issues that typically plague plant protein products during filling operations.

Does Newamstar provide specialized CIP/SIP solutions for plant protein residues?

Yes, we’ve developed enhanced CIP/SIP protocols specifically designed to address the unique cleaning challenges posed by plant protein residues. Our cleaning systems utilize optimized temperatures, specialized cleaning agents, and extended contact times to ensure complete removal of protein films and residues, preventing cross-contamination and ensuring proper sanitization between production runs.

Transform Your Plant Protein Production

Take your plant-based beverages to the next level with Newamstar’s advanced aseptic filling technology. Superior protein preservation, extended shelf life, and exceptional product quality await.

Global Plant Protein Technology Presence

With over 2,300 liquid product production lines successfully implemented across more than 100 countries and regions globally, Newamstar has established a worldwide footprint in plant-based beverage excellence. Our technology adaptability ensures optimal performance across diverse operating environments, climate conditions, and regulatory frameworks.

Regional Solution Adaptations

- Tropical Climate Solutions: Enhanced environmental control systems for high-humidity regions

- High-Altitude Installations: Specialized pressure control systems for elevated locations

- Cold Climate Implementations: Thermal protection systems for low-temperature environments

- Challenging Water Quality Regions: Enhanced water treatment capabilities

Global Regulatory Compliance

- FDA (Food and Drug Administration) requirements

- EHEDG (European Hygienic Engineering & Design Group) guidelines

- 3-A Sanitary Standards

- China NMPA regulations

- FSSC 22000 food safety management system requirements

- ISO 14159 (Hygiene requirements for machinery design)

Global Plant Protein Solutions Provider

Plant Protein Installations

Production Lines

Countries & Regions

Sterilization Technologies

From soy milk to almond beverages, and from oat drinks to innovative plant protein formulations, Newamstar has successfully implemented aseptic solutions across the full spectrum of plant-based alternatives worldwide.

Our expertise spans all plant protein beverage categories, with tailored solutions that address the unique challenges of each product type while maintaining the highest standards of quality and safety.

Complete Plant Protein Production Ecosystem

Maximize your investment with Newamstar’s comprehensive plant protein production ecosystem. Our integrated solutions work in perfect harmony to deliver exceptional efficiency, product quality, and operational excellence for all plant-based beverage applications.

Transform Your Plant Protein Production

Contact our plant protein aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can elevate your plant-based beverage manufacturing capabilities.

Why Choose Newamstar

Our plant protein filling systems exceed traditional filling technology in multiple key areas, providing significant competitive advantages

Plant Protein-Specific Sterilization Technologies

Newamstar has developed specialized sterilization technologies optimized for plant protein applications, ensuring both product safety and quality preservation for sensitive plant-based beverages.

Hydrogen Peroxide Dry Sterilization

- Process: Vaporized hydrogen peroxide application with precise temperature control

- Advantages: Zero water usage, enhanced sterility assurance for plant proteins

- Best for: Standard plant milks and flavored plant beverages

- Capacity range: 12,000 – 36,000 bottles per hour

Advanced PAA Sterilization

- Process: Enhanced peracetic acid application with residue-free validation

- Advantages: Reliable sterilization with proven plant protein compatibility

- Best for: High-volume plant-based production facilities

- Capacity range: 12,000 – 24,000 bottles per hour

Electron Beam Sterilization

- Process: Chemical-free sterilization for premium plant protein applications

- Advantages: Zero chemical residue, ideal for organic plant milks

- Best for: Premium plant-based and specialty nutrition products

- Capacity range: 24,000 – 48,000 bottles per hour

Customer Success Stories

Discover how Newamstar’s liquid product filling solutions are transforming production efficiency worldwide

Preform

Blow Molding

Filling

Capping

Labeling

Packaging

Newamstar’s Complete Innovation Journey

For nearly four decades, Newamstar has pioneered revolutionary advancements in beverage packaging technology. From our humble beginnings as Sanxing Sheet Metal Factory in 1986 to becoming a global leader in integrated packaging solutions, our history reflects our unwavering commitment to innovation and excellence.

Frequently Asked Questions

What types of beverages can be processed on Newamstar’s aseptic filling lines?

Newamstar’s aseptic filling systems can process a wide range of beverages including water, juices, teas, dairy products, plant-based milks, protein drinks, sports beverages, and other liquid food products. Our systems are designed to handle both high-acid (pH below 4.6) and low-acid (pH above 4.6) products.

What is the shelf life of products filled on Newamstar’s aseptic systems?

Products filled on our aseptic systems typically achieve shelf lives of 6-12 months without refrigeration, depending on the specific product characteristics and packaging materials used. Some products can achieve even longer shelf life with appropriate formulation and packaging.

What bottle sizes can be handled on Newamstar’s aseptic filling lines?

Our aseptic systems can handle PET bottles ranging from 250ml to 2.0L, with specific capacity ranges varying by system configuration. Custom solutions for other sizes may be available upon consultation.

How does Newamstar ensure the sterility of the packaging process?

Newamstar employs multiple sterilization technologies including PAA wet sterilization, hydrogen peroxide dry sterilization, and electron beam sterilization. The entire process occurs within a controlled cleanroom environment with HEPA-filtered air, positive pressure, and continuous monitoring of critical control points.

What is the typical installation time for an aseptic filling line?

Installation time varies depending on line complexity and capacity, but typically ranges from 3-6 months from equipment delivery to production qualification. Our experienced project management team works closely with customers to minimize downtime and ensure smooth implementation.

Does Newamstar provide training for operating personnel?

Yes, comprehensive training programs are included with all Newamstar aseptic systems. Training covers operation, maintenance, troubleshooting, and quality control procedures. Both on-site and factory training options are available.

Ready to Elevate Your Beverage Production?

Contact our aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can transform your beverage manufacturing capabilities.

Global Aseptic Technology Presence

With over 2,300 liquid product production lines successfully implemented across more than 100 countries and regions globally, Newamstar has established a worldwide footprint of excellence. Our technology adaptability ensures optimal performance across diverse operating environments, climate conditions, and regulatory frameworks.

Regional Solution Adaptations

- Tropical Climate Solutions: Enhanced environmental control systems for high-humidity regions

- High-Altitude Installations: Specialized pressure control systems for elevated locations

- Cold Climate Implementations: Thermal protection systems for low-temperature environments

- Challenging Water Quality Regions: Enhanced water treatment capabilities

Global Regulatory Compliance

- FDA (Food and Drug Administration) requirements

- EHEDG (European Hygienic Engineering & Design Group) guidelines

- 3-A Sanitary Standards

- China NMPA regulations

- FSSC 22000 food safety management system requirements

- ISO 14159 (Hygiene requirements for machinery design)

Global Aseptic Solutions Provider

Aseptic Installations

Production Lines

Countries & Regions

Sterilization Technologies

From fruit juices to dairy products, and from tea beverages to plant-based alternatives, Newamstar has successfully implemented aseptic solutions across a diverse range of applications worldwide.

Our expertise spans the full spectrum of liquid product categories, with tailored solutions that address the unique challenges of each product type while maintaining the highest standards of quality and safety.

Complete Aseptic Production Ecosystem

Maximize your investment with Newamstar’s comprehensive aseptic production ecosystem. Our integrated solutions work in perfect harmony to deliver exceptional efficiency, product quality, and operational excellence.

Transform Your Beverage Production

Contact our aseptic technology experts today to discuss your specific production requirements and discover how Newamstar’s advanced aseptic filling systems can elevate your manufacturing capabilities.