Medium-Pressure UV Technology in Aseptic Production

Aseptic filling technology involves filling commercially sterilized room-temperature materials under aseptically controlled conditions into sterilized containers. This technology brings numerous advantages such as extended product shelf life, improved taste, reduced energy consumption costs, and elimination of preservatives. As a result, this technology is rapidly replacing traditional hot-filling methods.

In recent years, with the trend of sustainable development, dry aseptic technology has gained rapid development and widespread application due to its low energy consumption, low emissions, and no need for water rinsing of packaging materials. Among successfully commercialized dry aseptic technology solutions, aseptic blow molding and electron beam bottle sterilization solutions have shown significant advantages, with energy consumption and emissions performance clearly superior to empty bottle VHP solutions and wet aseptic solutions.

“Currently, the most recognized dry aseptic solution in the market is the aseptic blow molding dry aseptic blow-fill-cap system.”

External Sterilization in Aseptic Blow Molding

For aseptic blow molding technology, the current core issue lies in the method of preform sterilization. For the sterilization of the inner surface of preforms, the industry generally adopts hydrogen peroxide, including but not limited to different technical approaches such as dry vaporized hydrogen peroxide (VHP), wet vaporized hydrogen peroxide (HPV), and atomized hydrogen peroxide.

For the sterilization of the outer surface of preforms, the main reliance is on ultraviolet light and VHP technologies. According to the provisions of 5.2.1 in “GBT 41124-2021 General Technical Requirements for Aseptic Blow-Fill-Cap Integrated Machines” [1], regardless of the technology used, the sterilization efficiency of the preform’s outer surface should reach ≥4 log (using Bacillus subtilis spores ATCC 9372 as the biological indicator).

Low-Pressure UV Sterilization

One industry company first pioneered the dry aseptic blow molding technology route. Their standard sterilization solution for the preform outer surface is low-pressure UV sterilization. Multiple sets of ∩-shaped low-pressure mercury amalgam UV lamps are arranged in the preform feeding channel and heating furnace area. When preforms enter the UV tunnel lamp assembly, their outer surfaces are completely exposed to multi-angle UV irradiation, achieving a log reduction value of ≥4 log per preform.

VHP Sterilization

Another industry company uses VHP for sterilizing the outer surface of preforms in dry aseptic blow molding technology. By exposing high-temperature preforms to a chamber environment with a certain VHP concentration for several seconds, they can achieve ≥5 log without VHP condensation.

Newamstar’s Medium-Pressure UV Approach

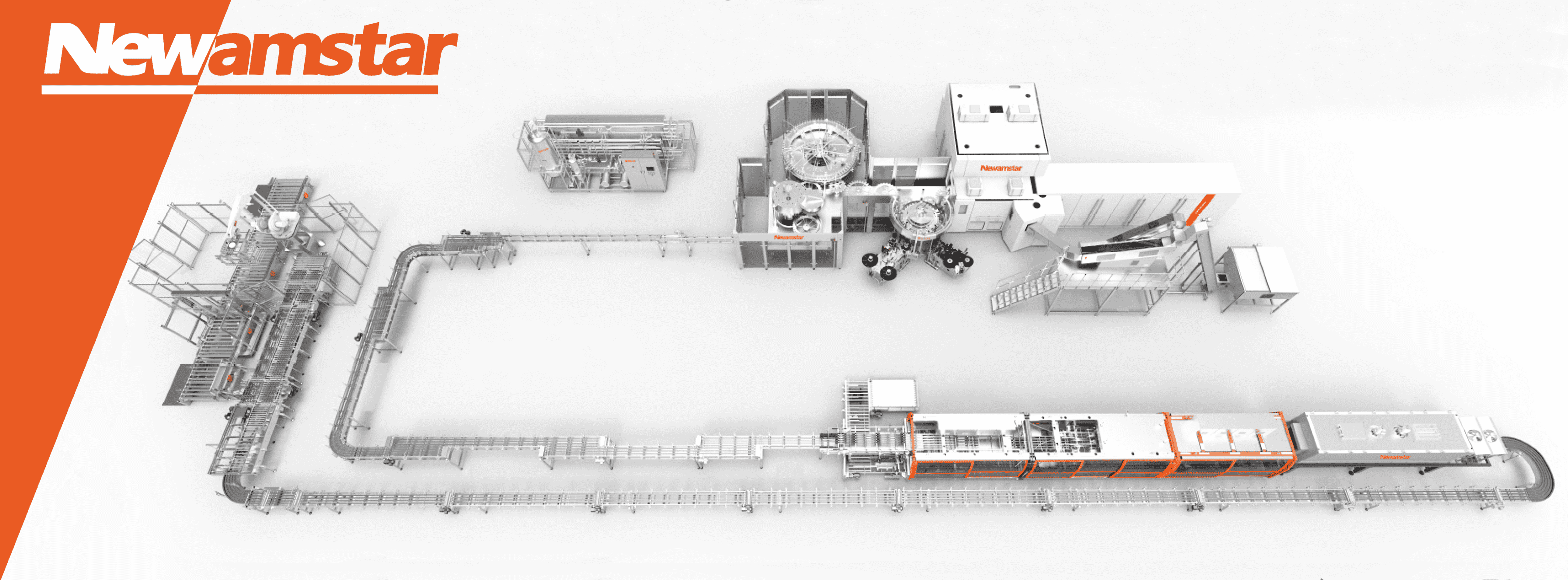

In the competitive domestic and international markets, Newamstar has become the first domestic equipment manufacturer to enter the field of aseptic blow molding technology. As a pioneer in China’s PET bottle aseptic filling industry and the earliest explorer of dry aseptic technology among Chinese counterparts, Newamstar has provided a distinctive solution. They innovatively selected medium-pressure UV to apply ultra-high-intensity UV irradiation to the outer surface of preforms, ultimately achieving the commercial sterilization requirement of ≥5 log reduction per preform.

Introduction to Ultraviolet Technology

Ultraviolet light is a safe, efficient, economical disinfection technology with no disinfection by-products. The industry mainly uses two types of products: low-pressure UV and medium-pressure UV.

Low-Pressure UV

Low-pressure UV lamps have an internal gas pressure of <10³ Pa. Common low-pressure UV lamps generally have power ratings of 10W to 800W. There are two different wavelength bands commonly seen in the market: 254nm UV that achieves sterilization through direct irradiation, and 185nm UV that completes fumigation sterilization by producing ozone.

Medium-Pressure UV

Medium-pressure UV has an internal gas pressure of 10⁴ Pa to 10⁶ Pa. The power of medium-pressure UV is generally between 1KW and 10KW, with continuous multi-spectral UV output. The UV excitation amount is particularly large in the optimal sterilization band of 240nm to 300nm.

Sterilization Mechanism Comparison

- Low-Pressure UV: Penetrates the cell membrane of microorganisms and acts on their internal DNA. After DNA molecules absorb ultraviolet light, adjacent pyrimidines on the same DNA chain connect to form pyrimidine dimers, preventing DNA replication and transcription, thereby achieving the effect of killing microorganisms [2].

- Photoreactivation Issue: Some microorganisms enter an inactive state after being irradiated with a certain dose of low-pressure UV lamp. After being irradiated with far ultraviolet or visible light, their internal DNA repair mechanism can reverse the DNA damage caused by UV radiation and regain activity, resulting in incomplete sterilization.

- Medium-Pressure UV Advantage: In addition to destroying microbial DNA, medium-pressure UV can also produce highly oxidative OH- free radicals, which achieve more thorough sterilization by destroying more microbial tissues to inhibit photoreactivation phenomena [3]. Furthermore, due to structural differences, different microorganisms have different absorption abilities and sensitivities to ultraviolet light of different wavelengths. Because medium-pressure UV has a wide band range, it can destroy different microorganisms through ultraviolet light of different wavelengths, giving medium-pressure UV greater broad-spectrum effectiveness compared to low-pressure UV.

UV Sterilization Design for Aseptic Blow Molding

The core objective of UV sterilization design for aseptic blow molding machines is to ensure that preforms achieve an outer surface sterilization efficiency of ≥4 log under any blow molding and UV conditions. The sterilization efficiency of ultraviolet light against different microorganisms corresponds basically to the UV dose value. The higher the dose received by the preform surface, the higher the sterilization intensity.

Therefore, by referencing technical literature, one can ascertain the UV dose required for a specified microorganism to achieve the rated sterilization efficiency. The UV dose required for Bacillus subtilis spores to achieve 4 log sterilization efficiency should be around 77mJ/cm².

According to the dose formula: Dose (mJ/cm²) = UV intensity (mW/cm²) × time (s), to achieve a higher dose level, one must either increase the UV irradiation intensity or increase the irradiation time. A common approach is to increase the lamp density in the lamp box to enhance irradiation intensity through increased distribution density. Additionally, tunnel-type lamp boxes are used with lamps arranged on both sides and top of the preform to maximize irradiation efficiency per unit time, while also arranging more sets of UV lamps to extend UV irradiation time.

“Newamstar’s medium-pressure UV solution directly increases the UV intensity emitted by the lamp per unit area. The UVC intensity on the surface of a 254nm low-pressure UV lamp is generally 20-25mW/cm², while Newamstar’s medium-pressure UV sterilization solution reaches 400-500mW/cm², achieving a 20-fold increase in unit area intensity.”

Through this massive increase in UV intensity, Newamstar has achieved reduced numbers of UV lamp sets, reduced equipment footprint, reduced number of lamps per set, reduced maintenance monitoring costs, and higher sterilization efficiency.

Key Technical Points in Medium-Pressure UV Application

While medium-pressure UV has advantages over low-pressure UV in terms of higher irradiation intensity, it also has corresponding disadvantages and technical challenges.

Lifespan Considerations

From a service life perspective, low-pressure lamps have a longer service life. Generally, after reaching the rated usage time of 8,000-13,000 hours, the UV intensity will decrease to 70%. The service life of medium-pressure UV lamps is highly associated with temperature control during operation. Under appropriate operating conditions, the UV intensity will slowly decrease to 70% after 3,000-7,000 hours of use. If the lamp is in an abnormal temperature control state, it will accelerate aging and degradation, leading to a significant reduction in UV output intensity.

Temperature Control

Taking the medium-pressure UV lamp used by Newamstar as an example, the surface of the lamp during operation needs to be controlled within the range of 550°C ±100°C. The filament material is tungsten, and the temperature of the tungsten filament approaches 2,700°C when the lamp is working, with the tungsten filament evaporating into tungsten vapor. Under the action of halogens inside the lamp, tungsten atoms return to the filament, forming a halogen cycle.

Operational Issues

If the exhaust fan draws too much air, causing the lamp temperature to be too low, it will break the halogen cycle. Tungsten atoms will adhere to the lamp wall, and as time progresses and tungsten sputtering reaches a certain level, the tungsten filament’s lifespan is exhausted, the lamp cannot start and extinguishes. This typically manifests as blackening at both ends of the lamp filament without air leakage. If the exhaust fan draws too little air and the lamp temperature is too high, the lamp will also show blackening, accompanied by whitening or air leakage.

Lamp Box Design

In the industry, medium-pressure UV is mainly used for water treatment sterilization or cap track sterilization, with lamp boxes generally designed as single-lamp independent boxes. Under these conditions, the box duct design and heat dissipation control have matured after many years of application and optimization. However, to apply it to the outer surface sterilization of preforms in aseptic blow molding machines, the lamp box requires completely new design.

Newamstar’s Innovative Approach

In all stages of the blow molding machine, the only place where the preform’s outer surface can be completely exposed to UV irradiation is inside the heating furnace. At this point, the core rod (also called the mandrel head) holds the inner surface of the preform mouth and rotates rapidly, allowing the outer surface of the preform to complete the UV sterilization process from all directions without blind spots.

Optimal Lamp Configuration

Based on the relative position and size relationship between the preform and the lamp, it can be found that one lamp cannot irradiate the outer surface of the preform without blind spots. Four lamps need to be arranged to irradiate from different positions to make the UV intensity on the preform surface relatively uniform.

Thermal Management Challenge

After lighting and running four lamps simultaneously in one lamp box, due to the high power and heat generation of medium-pressure UV lamps, the four lamps close to each other will also interfere with each other. Therefore, when using one cooling fan to cool four lamps, the duct design is particularly important. At the same time, designing a reasonable automatic temperature control system is also essential to ensure that each lamp always maintains the optimal working temperature range.

Comprehensive Monitoring System

Packaging material sterilization, as the most critical point in aseptic blow molding technology, requires stability and reliability. The equipment’s control system must be able to detect and identify the operating conditions of the lamps in real-time, including the voltage, current, operating time, and lamp intensity attenuation of each lamp. If there is an abnormal UV intensity, it must promptly alarm and stop production to ensure product safety.

Conclusion

As more and more aseptic blow molding dry aseptic lines are commercially put into production, their operational stability and product aseptic assurance levels are increasingly valued by enterprises. Preform outer wall sterilization, as an important link in aseptic blow molding machines to ensure product quality, requires efficiency, thoroughness, and stability in sterilization.

The adoption of medium-pressure UV design with an appropriate dose, combined with a reasonable control system, can make the outer surface of preforms achieve more efficient and broader spectrum sterilization effects, thereby ensuring the sterilization stability of this unit.