The Comprehensive Newamstar Aseptic Filling Guide

For beverage manufacturers considering aseptic filling technology, the decision-making process involves numerous questions spanning technical capabilities, operational requirements, economic considerations, and implementation approaches. This comprehensive FAQ addresses the most common inquiries about Newamstar’s aseptic filling technology, providing clear, detailed answers to support informed evaluation and implementation planning.

The questions are organized into logical categories, allowing readers to focus on aspects most relevant to their specific needs, whether they’re in the initial exploration phase or actively planning implementation. Each answer provides practical insights based on Newamstar’s extensive experience across global markets and diverse beverage applications.

Technology Fundamentals

Q: What exactly is aseptic filling technology, and how does it differ from other filling methods?

A: Aseptic filling technology involves separately sterilizing the product and packaging materials, then bringing them together in a sterile environment to create a commercially sterile product that remains shelf-stable without refrigeration or preservatives.

This differs fundamentally from other methods:

- Hot-fill sterilizes the container using the heat from the hot product itself (typically 85-95°C), requiring heat-resistant packaging and resulting in some quality degradation from extended heat exposure.

- Cold-fill with preservatives uses chemical preservatives to prevent microbial growth but avoids the quality impact of heat, though consumers increasingly reject preservative use.

- Tunnel pasteurization fills products at ambient temperature, then pasteurizes the sealed containers in a heating tunnel, requiring heavy packaging to withstand thermal stress.

- ESL (Extended Shelf Life) uses milder thermal treatment with clean filling conditions for moderate shelf life extension, but typically requires refrigeration.

Newamstar’s aseptic technology achieves commercial sterility while minimizing thermal impact on the product, enabling ambient distribution without preservatives and allowing lightweight packaging designs impossible with hot-fill or retort processes.

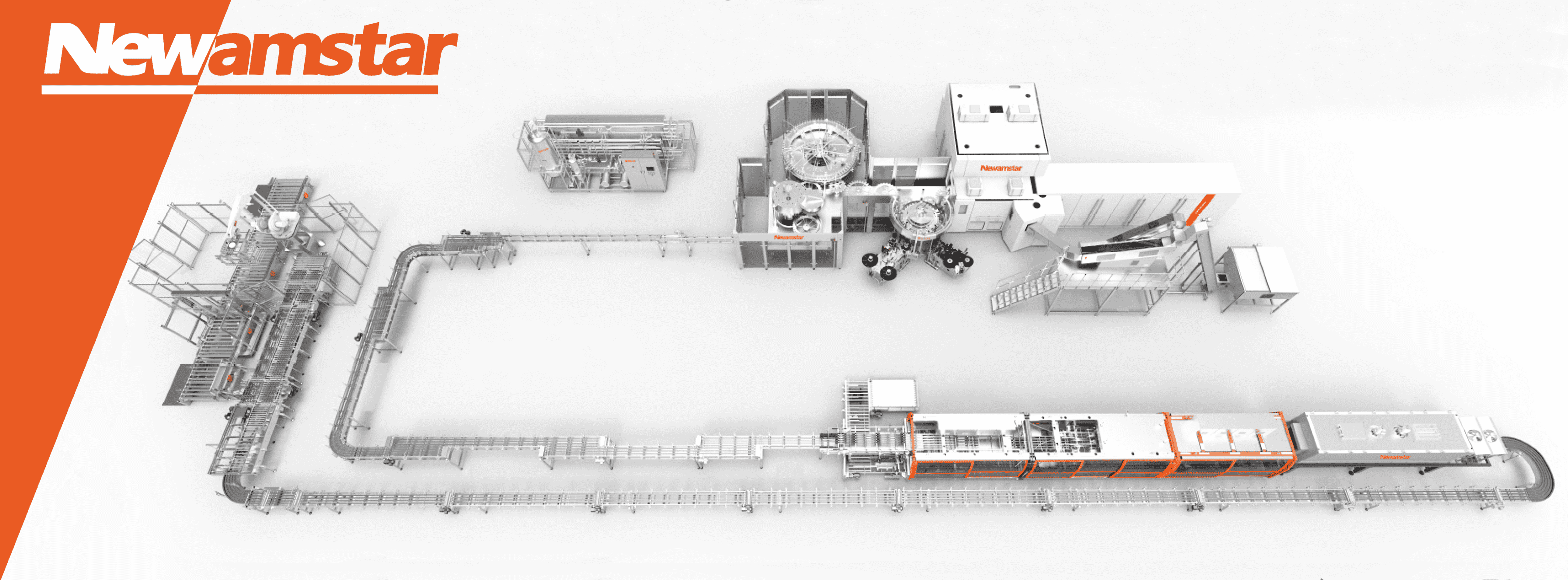

Q: What are the core components of Newamstar’s aseptic filling systems?

A: Newamstar’s aseptic filling systems comprise several integrated subsystems working together:

- Product Treatment System: Typically including:

- Ultra-High Temperature (UHT) processing module

- Homogenization systems (where required)

- Deaeration systems for oxygen-sensitive products

- Specialized treatment modules for specific formulations

- Aseptic surge tanks maintaining sterility between processes

- Sterilization Systems:

- Product sterilization via thermal or alternative technologies

- Container sterilization typically using hydrogen peroxide vapor, radiation, or heat

- Cap/closure sterilization with specialized technologies

- Environmental sterilization maintaining aseptic filling zone

- CIP/SIP systems for equipment sterilization

- Filling Technology:

- Non-contact filling valves preventing cross-contamination

- Electromagnetic or mass-flow metering for precise volume control

- Specialized filling systems for different product characteristics

- Inert gas management systems (where required)

- Aseptic transfer systems between sterile zones

- Environmental Control:

- HEPA filtration systems maintaining air quality

- Positive pressure barriers preventing contamination ingress

- Laminar airflow systems minimizing particulate movement

- Environmental monitoring systems verifying conditions

- Personnel and material access controls

- Control Systems:

- Integrated automation controlling all subsystems

- Process monitoring ensuring critical parameter maintenance

- Validation systems documenting sterility assurance

- Recipe management for different product formulations

- Traceability systems documenting production history

These components work as an integrated system to maintain product sterility throughout processing and packaging, with each element critical to overall system effectiveness.

Q: What product types and packaging formats can Newamstar’s aseptic technology handle?

A: Newamstar’s aseptic systems accommodate a wide range of product types and packaging formats:

Product Categories:

- Low-acid beverages (pH > 4.6) including dairy, plant-based alternatives, protein drinks

- High-acid beverages including juices, teas, coffee drinks, flavored waters

- Pulp-containing products with particles up to 10mm in size

- Viscous products up to 150 cP

- Carbonated products with specialized aseptic carbonation systems

- Hot-fill compatible products for hybrid processing approaches

Packaging Formats:

- PET bottles from 200ml to 5L in various designs

- Custom container designs with specialized neck finishes

- Multi-layer barrier bottles for oxygen-sensitive products

- Lightweight containers impossible with hot-fill technology

- Various closure styles including screw caps, sport caps, and custom designs

Specialized configurations are available for unique product characteristics or packaging requirements, with system customization based on specific application needs.

Q: What shelf life can products typically achieve with Newamstar’s aseptic technology?

A: Typical shelf life achievements vary by product category and packaging specifications:

- Low-acid beverages (pH > 4.6): 6-12 months at ambient temperature

- High-acid beverages (pH < 4.6): 9-18 months at ambient temperature

- Products with high vitamin content: 6-9 months with appropriate packaging

- Oxygen-sensitive products: 6-12 months with barrier packaging

- Light-sensitive products: 9-12 months with light barrier packaging

Actual shelf life depends on several factors:

- Product composition and inherent stability

- Packaging barrier properties

- Storage conditions (temperature, humidity, light exposure)

- Quality parameters defining end-of-shelf-life (sensory, nutritional, etc.)

Newamstar typically conducts shelf life studies during validation to establish documented shelf life for specific product-package combinations, with ongoing stability programs often identifying opportunities for shelf life extension as experience with specific formulations grows.

“Aseptic filling fundamentally changes product quality possibilities. By separating the sterilization process from packaging, manufacturers can deliver the highest quality beverages with minimal thermal impact while achieving extended shelf life without preservatives. This combination creates new opportunities for premium product positioning and distribution flexibility impossible with conventional technologies.”

Operational Considerations

Q: What production speeds can Newamstar’s aseptic systems achieve?

A: Newamstar offers aseptic systems across a range of production capacities:

- Standard commercial ranges: 6,000 to 80,000 bottles per hour

- Most common implementations: 24,000 to 48,000 bottles per hour

- High-speed systems: Up to 80,000 bottles per hour for water and CSD products

- Specialized high-capacity systems: Up to 108,000 bottles per hour (currently the highest capacity in Asia)

Actual production speed depends on:

- Product characteristics (viscosity, particulates, carbonation)

- Container size and design

- Closure type and application method

- Required filling precision

- Line configuration and layout

Systems are typically specified with 10-15% capacity margin above current requirements to accommodate future growth, with modular designs enabling capacity expansion in many cases.

Q: What utility requirements do these systems have?

A: Utility requirements vary based on system configuration and capacity, but typical requirements include:

Electrical:

- 380-480V, 50/60Hz, three-phase power

- Connected load typically 300-800kW depending on capacity

- Actual consumption approximately 60-70% of connected load

- UPS backup for critical control systems

Steam:

- Culinary-grade steam for product heating

- Industrial steam for CIP/SIP systems

- Typical consumption: 500-1,200 kg/hour depending on system size

- Pressure requirements: 6-10 bar

Water:

- Potable water for general use

- Purified water for product contact applications

- Typical consumption: 4-8 m³/hour during operation

- Closed-loop systems reducing consumption by 75-85%

Compressed Air:

- Oil-free, instrument-quality air for control systems

- High-pressure air for specific operations

- Typical consumption: 80-250 Nm³/hour

- Pressure requirements: 6-10 bar (standard) and 25-40 bar (high-pressure)

Cooling:

- Chilled water: 1-7°C for product cooling

- Tower water: 25-30°C for utility cooling

- Typical load: 200-800 kW thermal depending on capacity

Carbon Dioxide (for carbonated products):

- Food-grade CO₂

- Typical consumption: 0.4-0.8 kg per 100L of product

Detailed utility specifications are provided during project planning, with options for utility optimization based on local conditions and costs.

Q: What maintenance requirements should we anticipate?

A: Maintenance for Newamstar’s aseptic systems follows a structured approach:

Routine Maintenance (Daily/Weekly):

- Visual inspections of critical components

- Sensor calibration verification

- Sterile filter integrity testing

- Seal and gasket inspections

- Minor lubrication and adjustment tasks

Scheduled Maintenance (Monthly/Quarterly):

- Comprehensive preventive maintenance tasks

- Wear component replacement based on running hours

- Control system diagnostics

- Validation of critical parameters

- CIP/SIP system performance verification

Annual Maintenance:

- Major overhauls of key components

- Replacement of scheduled service items

- Comprehensive system calibration

- Revalidation of critical processes

- Software updates and security patches

Modern systems incorporate predictive maintenance capabilities using vibration analysis, thermal imaging, and performance trending to identify developing issues before failures occur.

Q: What personnel skills are required to operate and maintain these systems?

A: Successful operation requires several skill sets:

Operational Personnel:

- Line operators with basic technical understanding

- Process specialists for product formulation and thermal processing

- Quality assurance personnel for monitoring and verification

- Production supervisors with aseptic processing knowledge

- CIP/sanitation specialists for cleaning processes

Technical Support:

- Maintenance technicians with mechanical skills

- Electrical/electronic technicians

- Automation specialists for control system support

- Quality technicians for validation activities

- Engineering support for system optimization

Skill Development Approaches:

- Initial operator training (typically 4-6 weeks)

- Maintenance training (typically 2-3 weeks)

- Ongoing skill development programs

- Technical documentation and reference materials

- Remote support from Newamstar specialists

Newamstar provides comprehensive training programs during implementation, with options for refresher training and specialized technical courses.

Q: How long does implementation typically take?

A: Implementation timelines vary based on project scope, but typical timeframes include:

Project Phases:

- Initial specification and design: 2-3 months

- Equipment manufacturing: 4-6 months

- Factory acceptance testing: 2-3 weeks

- Shipping and delivery: 1-2 months

- Installation: 4-8 weeks

Remaining Phases:

- Commissioning: 2-4 weeks

- Validation: 2-6 weeks

- Production ramp-up: 1-3 months

Total timeline from contract to commercial production:

- Standard projects: 12-16 months

- Fast-track projects: 9-12 months

- Complex implementations: 16-20 months

Factors affecting timeline include facility readiness, regulatory approval processes, product complexity, customer resource availability, and global logistics conditions. Newamstar provides detailed project management with critical path analysis and regular progress updates throughout implementation.