Minimizing Downtime with Newamstar Aseptic Technology

In the competitive beverage industry, production reliability directly impacts profitability, market responsiveness, and brand reputation. Aseptic filling systems represent significant capital investments, making their consistent performance and maximum availability crucial business concerns. While technological sophistication delivers product quality and operational efficiency, these benefits are only realized when systems operate reliably with minimal unplanned downtime.

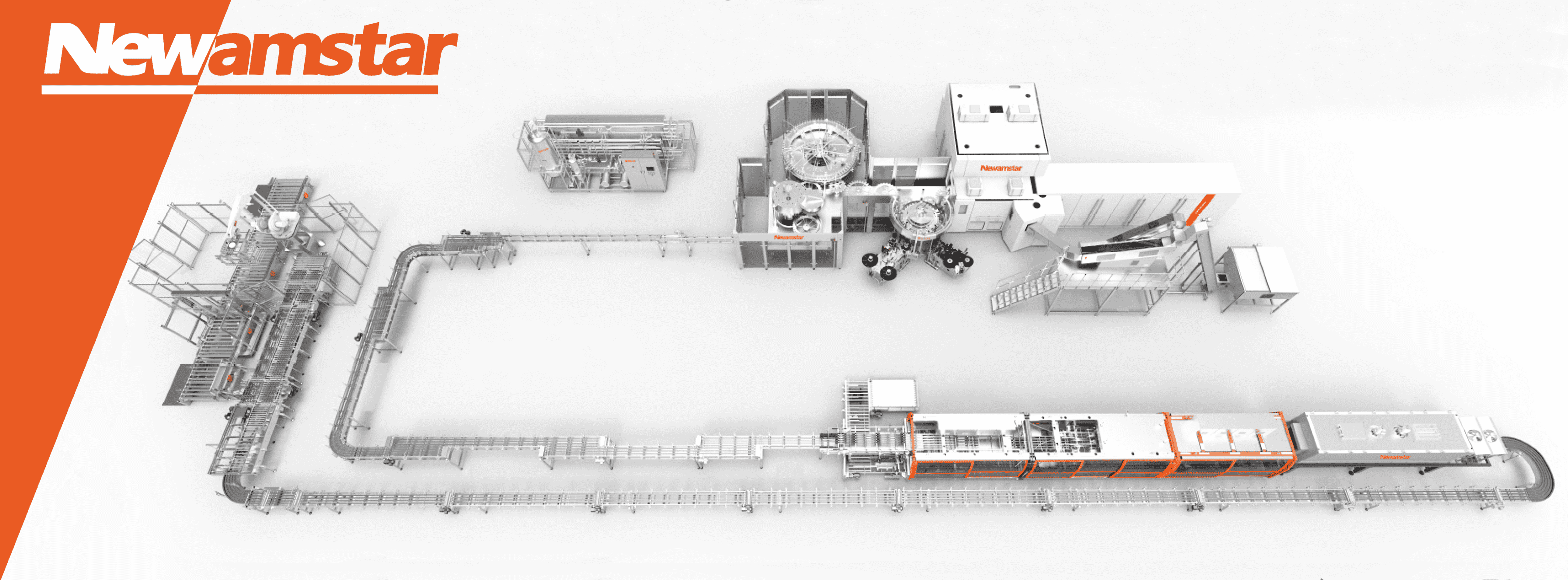

Newamstar’s aseptic filling technology has earned recognition not only for its advanced capabilities but also for its exceptional reliability and maintainability. This article explores the design philosophy, maintenance strategies, and operational practices that ensure Newamstar’s systems deliver industry-leading uptime while maintaining aseptic integrity throughout extended production runs.

Design for Reliability: The Foundation of Uptime Excellence

Reliability begins not with maintenance practices but with fundamental design principles. Newamstar incorporates reliability engineering from the earliest design phases, creating systems with inherent dependability.

Component Selection Philosophy

The foundation of reliability lies in component selection, where Newamstar follows several key principles:

Quality-First Sourcing

Critical components sourced exclusively from tier-one global manufacturers, with rigorous supplier qualification criteria and regular performance evaluation to ensure consistent quality.

Design Margin Engineering

Rather than designing to minimum specifications, mechanical components are specified with 30-50% capacity margins above maximum requirements, ensuring components operate within optimal performance ranges.

Redundancy Implementation

Critical systems incorporate strategic redundancy with parallel sterile air filtration, backup sterilant dosing systems, and a fail-operational design philosophy to prevent single-point failures.

Modular Architecture

Functionally independent subsystems with standardized interfaces enable rapid replacement of components and isolation capabilities for maintenance without complete system shutdown.

Aseptic Integrity Through Reliability

For aseptic systems, reliability transcends operational continuity—it directly impacts product safety. Newamstar’s design approach recognizes this critical relationship:

Aseptic Safety Features

- Fail-safe designs defaulting to product protection during abnormal conditions

- Redundant monitoring of critical aseptic parameters

- Self-diagnostic capabilities identifying potential aseptic compromises

- Early warning systems detecting developing issues before failures occur

- Automated responses maintaining sterility during transient conditions

Preventive Maintenance Strategy: Beyond Break-Fix Approaches

While design creates the reliability foundation, proper maintenance practices preserve and enhance performance throughout the system lifecycle. Newamstar’s preventive maintenance strategy incorporates several advanced approaches:

Condition-Based Maintenance

Moving beyond traditional time-based schedules to implement vibration analysis, thermal imaging, and performance trend analysis for maintenance based on actual component condition.

Risk-Based Prioritization

Using failure mode and effects analysis (FMEA) and risk matrices to prioritize maintenance activities delivering the greatest reliability impact and return on investment.

Precision Maintenance

Implementing precision alignment procedures, torque specification compliance, and verification procedures to prevent maintenance-induced failures in complex systems.

Digital Work Management

Supporting maintenance execution through detailed electronic work instructions, digital documentation, and mobile access to technical resources for field personnel.

Predictive Technologies: Anticipating Needs Before Failures

Beyond preventive maintenance, Newamstar incorporates advanced predictive technologies identifying potential issues before they impact performance:

Advanced Monitoring Systems

Comprehensive real-time tracking of performance parameters against established baselines with automated anomaly detection to identify unusual patterns before they lead to failures.

Machine Learning Applications

Leveraging artificial intelligence for pattern recognition to identify non-obvious failure precursors and predictive models that forecast remaining useful life of components.

Remote Diagnostic Capabilities

Secure remote access for specialist technical support with real-time system performance monitoring from Newamstar’s support centers, reducing response time and improving resolution speed.

Digital Twin Technology

Virtual representations of physical systems enable real-time comparison between expected and actual performance, with simulation capabilities for testing maintenance approaches before implementation.

Spare Parts Strategy: Ensuring Availability When Needed

Even with sophisticated predictive approaches, component replacement remains necessary for optimal system maintenance. Newamstar’s comprehensive spare parts strategy ensures timely availability:

“Newamstar maintains regional parts distribution centers strategically located to serve global markets, with hubs in Shanghai, Frankfurt, Atlanta, Dubai, and Singapore. These centers maintain inventories of all critical and essential spares, with expedited delivery capabilities ensuring parts availability within 24-48 hours globally.”

Strategic Parts Classification

Tiered classification approach categorizing components as critical spares, essential spares, regular consumption items, or convenience items to drive appropriate inventory strategies.

Customer-Site Inventory

Customized on-site inventory recommendations with tailored parts kits for specific system configurations and automatic replenishment programs ensuring consistent availability.

Parts Quality Assurance

Identical specifications to original equipment components with full traceability from manufacturing through installation and comprehensive testing before distribution.

Vendor Managed Inventory

VMI options for critical components balance inventory investment against downtime risk, optimizing parts availability at minimal holding cost.

Maintenance Program Implementation

Translating maintenance concepts into operational practice requires comprehensive implementation support. Newamstar provides structured programs ensuring reliability concepts become operational reality:

Tiered Maintenance Training

Progressive programs from basic operation to master-level system expertise develop appropriate skills at each organizational level within customer organizations.

Documentation Systems

Interactive electronic maintenance manuals with visual guides and video demonstrations ensure consistent maintenance execution while preserving institutional knowledge.

Maintenance Service Programs

Flexible options from comprehensive maintenance contracts to technical advisory services allow customers to balance internal capabilities with external support.

Continuous Improvement

Regular reliability performance reviews and root cause analysis create a closed-loop improvement process that evolves maintenance practices based on operational experience.

Key Performance Indicators

Effective maintenance management requires objective performance measurement. Newamstar employs comprehensive KPI systems:

Industry-Leading Performance Metrics

Case Studies: Reliability Excellence in Action

The effectiveness of Newamstar’s reliability approach is demonstrated through consistent performance across diverse operating environments:

High-Volume Asian Beverage Producer

Achieved 98.7% average OEE across five production lines with 850 hours MTBF exceeding industry benchmarks by 40%. Zero sterility failures over 18 months of continuous operation and 35% reduction in maintenance costs compared to previous technology.

Middle Eastern Operation in Challenging Environment

Despite harsh desert conditions and limited local technical resources, achieved 97.5% OEE with temperatures regularly exceeding 45°C. Remote diagnostic support resolved 82% of issues without on-site visits, with 24/7 operation maintained for 120 consecutive days during peak season.

European Premium Producer with Complex Portfolio

A producer with over 40 SKUs achieved average changeover time reduction of 45% through optimized maintenance procedures and 99.1% OEE despite frequent product changes. Implementation of condition-based maintenance reduced scheduled downtime by 32% with zero product quality incidents.

Future Trends: The Evolution of Maintenance

Newamstar continues developing next-generation maintenance approaches incorporating emerging technologies:

Augmented Reality Support

Real-time visual guidance during maintenance procedures with remote expert overlay providing live assistance and step-by-step verification ensuring proper execution.

Advanced Robotics

Robotic inspection systems for routine condition monitoring and automated cleaning processes, with collaborative robots assisting human technicians for improved consistency.

AI Evolution

Self-optimizing systems adjusting parameters to extend component life with cognitive maintenance assistants guiding troubleshooting and natural language processing for knowledge retrieval.

Autonomous Maintenance

Computer vision systems for automated inspection with self-maintaining components featuring built-in diagnostic capabilities and autonomous maintenance schedule optimization.

The Competitive Advantage of Reliability

Newamstar’s approach to aseptic system reliability and maintenance delivers benefits extending far beyond simple uptime improvements. For beverage manufacturers navigating competitive markets with demanding quality requirements and tight margins, this reliability-focused approach provides a meaningful competitive advantage.

By transforming maintenance from a necessary cost center to a strategic value driver, these systems help manufacturers achieve operational excellence while maintaining the absolute safety assurance essential for aseptic production.

Global Impact and Industry Recognition

Throughout its evolutionary journey, Newamstar has successfully delivered over 2,300 production lines to customers across more than 100 countries and regions worldwide. The company’s aseptic filling technology has been embraced by international beverage giants including Coca-Cola, PepsiCo, Danone, and Nestlé, as well as leading domestic brands like Master Kong, Wahaha, and Nongfu Spring.

As a testament to its technical excellence, Newamstar has received numerous industry accolades and holds over 500 invention patents, many specifically related to aseptic filling innovations. This recognition reflects not only the company’s technological capabilities but also its commitment to driving industry advancement.

Key Achievements in Aseptic Filling Technology

The Strategic Value of Reliability

Through comprehensive design for reliability, advanced maintenance methodologies, and continuous evolution of predictive technologies, Newamstar ensures its aseptic filling systems remain at the forefront of not only technological capability but also operational dependability—delivering the consistent performance essential for success in today’s demanding beverage markets.

Strategic Benefits Beyond Uptime

- Product Safety Assurance: Consistent aseptic performance protecting brand reputation

- Production Planning Confidence: Reliable systems enabling lean inventory and responsive scheduling

- Total Cost Optimization: Reduced downtime and maintenance costs improving overall economics

- Extended Asset Lifecycle: Proper maintenance maximizing return on capital investment

- Operational Excellence Foundation: Reliable equipment enabling continuous improvement initiatives

“For beverage manufacturers navigating competitive markets with demanding quality requirements and tight margins, Newamstar’s reliability-focused approach provides a meaningful competitive advantage. By transforming maintenance from a necessary cost center to a strategic value driver, these systems help manufacturers achieve operational excellence while maintaining the absolute safety assurance essential for aseptic production.”